When you are starting out in pottery, most likely someone else is firing your pieces. Or perhaps you have a new kiln and you are wondering about firing schedules. Either way, you are probably wondering, how long does it take to fire clay in a kiln? This article is all about how long the firing process takes for pottery….

Clay is normally fired twice. The first firing, or bisque fire, takes around 8-10 hours. And the second, or glaze firing takes around 12 hours. So, in total, it takes about 22 hours to fire clay in a kiln. Time for the kiln to cool adds to this total too.

There is no getting away from it, firing pottery takes time and patience. There are some things that you can do to speed the process up. However, clay is going through some big changes when it’s if fired. And these processes need to be undertaken gradually if your pottery is to survive being fired.

Let’s take a look at the different stages of firing clay and consider how long they take and why.

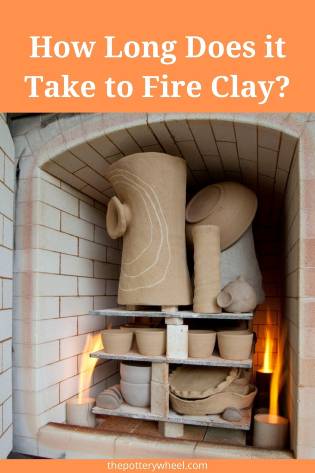

Bisque Firing Clay

Usually, the firing process is split into two stages and the clay is fired twice. The first stage is called the bisque or biscuit fire.

This is the part of the firing process where the pottery turns from clay to ceramic material. After you have made your piece of pottery, you let it dry out thoroughly before firing. When it is as dry as it can be, it is called ‘bone dry’ pottery.

Even though bone dry clay is solid, it is not very strong and will crumble easily. Also, it is still soluble in water. So, if you put unfired dry clay in water it will dissolve. The purpose of the bisque fire is to transform the clay from fragile, soluble material.

During the bisque fire, it is converted into a hard, porous but insoluble ceramic material. If it is put in water after the bisque fire, it will absorb the water but it won’t dissolve.

Whilst clay is in a bisque fire, it undergoes important physical and chemical changes. And these processes take time. In fact, typically a bisque fire will take around 10 hours.

Why Does a Bisque Fire Take So Long?

The length of time it takes to bisque fire depends on a few factors. These factors are:

The Target Temperature:

The target temperature is the temperature that the kiln has to reach for the firing schedule to be complete. Some potters bisque fire to cone 06 and others bisque fire to cone 04.

The cone system measures the time and temperature it takes to fire clay. Cone 06 is a target temperature of around 1823F (995C). And cone 04 is a target temperature of around 1940F (1060C).

Firing to a hotter target temperature will take a little longer. For example, you might set your kiln to rise at a rate of 108F per hour. At this rate, it will take about an hour longer to reach cone 04 temperatures than cone 06.

The Heating Rate:

All kilns, no matter what the design, can be adjusted to increase the temperature either slowly or more quickly. Some kilns use digital control panels, and others use dials and knobs. But either way, the heating rate can be controlled.

The rate at which the kiln heats up will affect how long the firing schedule takes. Let’s say your kiln is heating up at a rate of 108F per hour. Then reaching 1823F will take just under 17 hours. At a heat rate of 270F per hour, the same target temperature will be reached in just under 7 hours.

In fact, firing schedules usually have some segments that increase at a slower rate. And some segments increase at a faster rate. But you get the picture. The rate of increase will affect the answer to the question ‘how long does it take to fire clay’.

How Long Does It Take to Fire Clay During a Bisque Fire?

A good rule of thumb is that it will take around 10 hours to bisque fire pottery. However, some potters choose to bisque fire quickly. This means they might choose a lower target temperature. Or they might fire their clay at a faster rate. So, their firing time might be closer to 8 hours.

There are a few reasons for choosing to bisque fire faster. They might be production potters, making large batches of pottery on a mass scale. For production potter time really is money, and they need to save time where they can. Schools also are often up against deadlines, and might bisque fire more quickly.

Nevertheless, it’s often said that when bisque firing, it’s best to take it slow if you can. The reason for this is that, as stated above, the clay is going through a lot of change. And if possible, it’s best to allow these changes to occur slowly. Rushing the process can lead to problems.

Why is it a Good Idea to Bisque Fire Slowly

Clay should be bone dry when the bisque fire begins. Bone dry clay is as dry as it can be. However, even bone dry clay will contain some moisture nestled at its deeper levels. This water, which is referred to as ‘mechanical water’, needs to evaporate slowly as the bisque fire begins.

When moisture reaches the temperature of boiling water, at 212F (100C), it turns to steam. When it turns to steam it expands quickly. If moisture turns to steam in clay, the steam will expand into small air bubbles in the clay. This puts the clay under a lot of pressure and can cause it to explode in the kiln.

To avoid this, it’s important that the first part of the bisque firing schedule is slow. This will allow any moisture to evaporate before the kiln reaches 212F (100C).

In fact, most potters will set their kiln to do a pre-heat. This is also called ‘candling’ and involves setting the kiln to hover around a temperature just below boiling point. Often a pre-heat is set for 2 hours or more, to ensure that the clay is thoroughly dry.

During the bisque fire, other substances are burned out of the clay. These are carbons, organic material, and minerals. They burn out at different temperatures during the bisque fire.

It’s important that these substances are burned out sufficiently. If the bisque fire is too fast, some of these components can be left behind in the bisque ware.

This can cause problems later on in the glaze fire. The glaze fire is the second stage in firing clay, so let’s take a look at the glaze fire now….

Glaze Firing Clay

After the bisque fire, the pottery is unloaded from the kiln. It is then decorated with pottery glaze, allowed to dry, loaded back into the kiln, and fired again.

Pottery glaze is made up of ceramic materials suspended in water. It’s a liquid that is applied to the bisque pottery. Because bisque pottery is very porous it draws the water out of the glaze. This leaves the glaze materials behind on the bisque surface in a fragile, dry, powdery coating.

During the glaze firing, several things happen to the pottery. The clay itself continues to mature and harden in the glaze fire. And the pottery glaze melts to form a glassy layer on the pottery.

Pottery glaze has a couple of functions. One of these functions is decorative, providing color, texture, and design to the pottery. The other function is practical. The glassy layer that glaze creates on the pottery makes the clay either water-resistant or waterproof.

This means that the ceramic ware is no longer porous, and can be used as dinnerware or to hold liquid. Different types of clay are stronger and more waterproof than others. But essentially, glazing your pottery will protect it and make it look nice too.

What Happens to Glaze During the Glaze Fire

Pottery glaze has a number of ingredients that affect how it looks and behaves. But all glazes contain 3 basic ingredients to which others are added. The basic ingredients are, a glass-former, a flux, and a stabilizer.

The glass-forming substance produces glass when it melts at high temperatures. Silica is usually used as the glass former. The flux lowers the temperature at which silica melts. And typically frit is used as the flux.

The last core ingredient is a stabilizer, which helps the glaze adhere to the surface of the pottery. Alumina is often used as a stabilizer. It prevents the glaze from slumping off the pot during the glaze firing.

These ingredients, in addition to the colorants in the glaze, undergo chemical changes in the glaze fire. The glaze will melt, bubble, flow, and eventually settle down and smooth out during the glaze fire.

A glaze firing schedule needs to be long enough to ensure that these processes are complete. If the glaze firing isn’t long enough, problems can occur. Either the glaze won’t have melted and will look matte. Or, if the glaze hasn’t had a chance to settle down and smooth out, then the glaze might be blistered.

In addition to this, the glaze has to cope with any gases that are being emitted by the clay too. Carbonaceous matter, organic compounds, and chemicals may have been left behind in the clay during the bisque fire. As these burn out during the glaze fire, they create gases, that need to pass through the glaze.

If the glaze fire is too short, gases from the clay won’t have a chance to pass through the glaze. This can cause the pottery to bloat or for pinholes to form in the glaze surface.

How Long Does it Take To Fire Clay in a Glaze Fire?

So, all in all, the glaze and the clay are undergoing a lot during the glaze fire. And this takes time. This is why it’s not uncommon for a glaze fire to take around 12 hours.

The exact time it takes to glaze fire depends on a few factors. As with bisque firing, it depends on the target temperature and the heating rate. If you are firing low fire earthenware clay and glaze, then you don’t have to reach higher firing temperatures. As such the kiln will reach its target temperature sooner.

By contrast, if you are firing to stoneware temperatures it will take longer for the kiln to reach its target.

The time it takes to glaze fire also depends on the kiln itself. A new kiln will work more efficiently and will reach its target temperature more quickly. By contrast, an older kiln is likely to be a bit slower. This is particularly the case if you are firing to higher stoneware temperatures. The heating rate will start to slow down at higher temperatures if the kiln is a bit older.

As a result, a new efficient kiln might take 10 hours to glaze fire pottery. Whereas an older kiln might take around 13 hours to get to the same target temperature.

How Long Does it Take to Fire Clay – Other Factors at Play

There are a couple of other factors to consider when answering the question ‘how long does it take to fire clay’. These factors are:

Soak Time

Adding a soak time can help ensure that the glaze has settled down, smoothed out, and matured. A soak is a short period of time in a firing schedule, where the temperature is held static.

At the end of a particular segment in a firing schedule, the temperature is set to hold steady. This can last for 2 minutes or longer.

A soak is also known as a ‘hold’ or a ‘dwell’. There is quite a bit of debate around how long a kiln should be left to soak. Some potters and kiln manufacturers argue that a soak should be for no longer than 5 minutes. The argument is that anything longer is unnecessary and tough on the kiln elements. However, other kiln suppliers will recommend holding the kiln for 20-30 minutes.

If you want to know more about holding the kiln, you can check out this article.

Cooling the Kiln

Another factor that affects how long it takes to fire clay is the cooling period. A kiln needs to cool down before you open it. Ideally, the kiln should be at room temperature before you unload it.

Some potters will open their kiln a little earlier than this when it is still a bit hot. But there are risks attached to doing this. If you open a kiln when it’s still hot, say 212F (100C) and above, then you risk the pottery cracking.

This is because when the cool air hits the hot pottery, the ceramic can experience thermal shock. Thermal shock is when there is a sudden change in temperature.

If the pottery cools very rapidly, it contracts. If this puts the ceramics under enough stress, it can cause the pottery to crack. And even if the pottery doesn’t crack, it can cause the glaze to crack and craze. So, it’s best to wait until thermal shock is not a risk.

As a rule of thumb, it takes a kiln at least as long to cool down as it did to heat up. And if your kiln is large, or if it is tightly packed it will take longer to cool.

If my kiln is tightly packed it takes about 1 ½ times as long to cool down. If it takes 10 hours to bisque fire, it will take another 15 hours to be cool enough to open.

So, cooling time will increase how long it takes to fire clay considerably.

Final Thoughts

When you are figuring out how long does it take to fire clay, you need to factor in a few things. There is the bisque fire, the glaze fire, and the cooling time to consider. Realistically it takes a couple of days rather than hours to convert greenware pottery to the finished glazed item. The bisque fire plus cooling time can be around 24 hours. And similarly, the glaze fire plus cooling will take around 24 hours give or take, depending on how efficient your kiln is. So, it’s not a short process. But it’s worth the wait. It’s a cliché I know, but good things come to those who wait.