An experienced potter can make throwing pottery on a wheel look effortless. But what is going on when pottery is being made on the wheel, and exactly how does a pottery wheel work? This post takes a look at how pottery is thrown, and how a pottery wheel works.

A pottery wheel has a circular plinth or wheel head that rotates whilst the potter’s hands are free to shape the clay. The potter uses pressure against the centrifugal force of the clay to shape it. The wheel head can be made to move manually, or with an electric motor.

There are two strands to the question of how a pottery wheel works. The first strand is how the wheel is actually used by the potter. And the second strand is about how the pottery wheel is actually built.

These are some of the areas of this topic that I will cover in this article. Please feel free to jump to a section that catches your eye using the links below.

- How Does a Potter Use the Wheel?

- How the Clay is Shaped (or Formed)

- The Various Uses of a Pottery Wheel

- How does a Pottery Wheel Work?

- Manual Pottery Wheels

- Electric Pottery Wheels

- How Does Belt Drive Pottery Wheel Work?

- How Does a Direct Drive Pottery Wheel Work?

- Controlling the Speed of a Pottery Wheel

- Different Kinds of Pottery Wheel

- The History of the Pottery Wheel

Let’s take a look at how the wheel is actually used by potters to make pottery.

How Does a Potter Use the Wheel?

To look at, the main feature of a pottery wheel is a rotating circular metal disc. This is called the wheel head. The wheel head is attached to a shaft (or pole) that disappears into the body of the wheel.

Usually, there is a plastic pan that sits beneath and around the wheel head. If your pottery wheel is an older model, this might be wooden or metal. This is called the splash pan.

The splash pan is designed to catch any water, clay, or slip that comes of the pottery as it’s being formed.

Most pottery wheels are powered by electric motors these days. However, there are different manual designs that don’t rely on electricity. We will take a look at those later.

How the Clay is Shaped (or Formed)

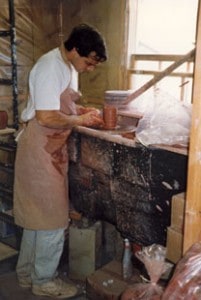

Clay is placed on the center of the wheel head or on a wooden bat that attaches to the wheel head. The potter then uses their hands to shape the clay as it turns on the wheel.

The clay needs to be wet and slips under their hands and fingers. Potters use a combination of pressure and finger and hand position to form the pottery.

The wheel relies on the principle of centrifugal force. This is the tendency for material to be thrown outwards from the center of a rotating wheel.

The potter uses their hands with and against the centrifugal force to shape the clay (source). This process is known as throwing on the wheel.

The Various Uses of a Pottery Wheel

Throwing pottery is one of the main uses of a pottery wheel. However, the wheel can be used for other tasks that are key to making pottery. These include:

Trimming Pots

Once the thrown pot has firmed up and become leather hard, it is positioned on the wheel head again. The simplest way of attaching it back onto the wheel is to stick it down with some lugs of clay. Lugs are small sausages of clay that press up against the edge of the pot and onto the wheel head.

The potter then uses a combination of ‘trimming tools’ to take off excess clay from the pot. Trimming also tidies up the shape of the pot and enables the potter to make a foot ring for the piece too.

Adding Decoration

The potter’s wheel can also be used to add decoration to a piece of pottery. For example, it can be used to add colored slip or glaze to a piece. Or to apply a layer of terra sigillata to a bone dry pot.

A wheel can also be used to add textures to a pot that has already been thrown. An example of this is ‘chattering’. Chattering is when a potter lays a metal tool against the surface of the pot. As the wheel turns the tool gouges out small pieces of clay at regular intervals on the surface. This creates a regular patterned texture on the surface of the pot.

So, that is the basic principle behind using a pottery wheel. But, what is going on behind the scenes? And how does a pottery wheel work? Let’s look at the mechanics of the wheel in the next section…

How Does a Pottery Wheel Work?

The mechanics of how a pottery wheel works have changed over time. Most pottery wheels today are run on electricity. However, early pottery wheels were manually operated by hand or foot.

I will say a little bit more about the history of the pottery wheel later. However, for now, let’s take a look at the difference between manual wheels and electric wheels. And consider how these different types of pottery wheel work.

Manual Pottery Wheels

There are two main types of manual pottery wheels, they are the kick wheel and the treadle wheel.

The Pottery Kick Wheel

On the kick wheel, the wheel head is mounted on a shaft. On the other end of the shaft is a flywheel that is positioned just by the potter’s feet.

Usually, a kick wheel has an integrated seat, the angle, and height of which can be adjusted to suit the potter. The wheel head is level with the potter’s hands and the flywheel sits at the base of the wheel close to the ground.

A flywheel is a large heavy wheel that takes a lot of force to get moving. Once it’s moving it has a lot of momentum, and it also requires a lot of force to stop it. Because it has a lot of momentum, it stores a lot of energy.

The flywheel and the wheel head are attached to opposite ends of the same shaft. So as the flywheel turns, the wheel head turns too.

The potter uses his or her foot to turn the flywheel. It can be tricky to get the flywheel moving as it’s so heavy. However, it’s a skill, and once learned, the wheel can be kicked to move around smoothly.

Using a kick wheel has a rhythm. Generally speaking, the potter does not kick as they throw the pot. Rather they kick the flywheel a few times and get up some speed, then they throw. So, the pattern is to kick then throw, kick then throw.

Because the kick wheel relies on momentum, it is known as a momentum wheel.

The Treadle Wheel

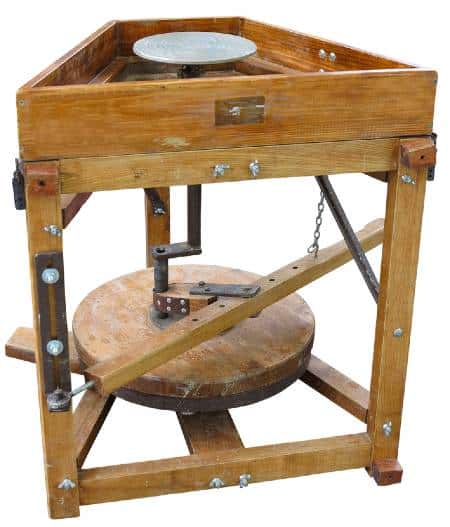

A treadle wheel also uses a flywheel that is near the floor to move the wheel head.

However, instead of kicking a heavy flywheel, the potter uses their foot to repeatedly move a wooden arm at the base of the wheel.

The wooden arm is attached to a sequence of shafts that in turn the flywheel. This in turn causes the wheel head to rotate.

It looks a little like the motion that was used on old non-electric sewing machines. The potter’s leg continues to gently swing on the moving arm to make the wheel head turn.

The Electric Pottery Wheel

An electric wheel is driven by an electric motor that has a lot of torque or rotational force.

Most often pottery wheels are belt-driven, however, some are direct drive. Let’s take a quick look at the difference between the two…

How Does a Belt Drive Pottery Wheel Work?

With a belt-drive, the motor is connected to a flywheel by a rubber belt. Unlike the kick wheel, the flywheel used on an electric wheel is usually lightweight and metal.

As the motor turns, the belt moves. This in turn makes the flywheel rotate. A shaft is attached to the flywheel. And the wheel head is attached to the other end of the shaft. So, as the flywheel turns, the wheel head turns too. Some examples of pottery wheels that use a belt drive are Brent and Skutt.

How Does a Direct Drive Pottery Wheel Work?

With a direct drive, the motor is directly driving the wheel head. The motor shaft is joined directly to the wheel head shaft. So, the speed of the motor directly affects the speed of the wheel head. Some examples of models that use a direct drive arrangement are Shimpo and Venco.

Controlling the Speed of a Pottery Wheel

On many wheels, the speed at which the motor runs is controlled by a foot pedal. Most foot pedals contain a potentiometer. This is a little electrical component, that can vary the voltage of an electrical current.

When the pedal is pressed the potentiometer increases the voltage of the supply that goes to the motor. This in turn increases the speed at which the wheel head turns. (Source 2)

Some wheels have a hand control lever. Others like tabletop wheels have a knob or toggle to control the speed of the wheel head.

More Types of Pottery Wheel

In addition to the types of pottery wheel described above, there are alternative models.

Standing Wheels

Some pottery wheels are designed to be used whilst the potter is standing. This approach to wheel throwing is often chosen for ergonomic reasons. Namely, it can be less tough on the potter’s back, wrists, and hands to throw whilst standing.

Robert Compton Pottery

Upside Down Wheels!

Not all pottery wheels have an upright horizontal wheel head. Some wheels are designed with the wheel head at an angle. These are used for throwing bowl shapes. (source: Hamer, F. and Hamer, J. 1975).

Other pottery wheels are horizontal but upside down. These wheels are helpful for making long tall pieces. It’s possible to make long tall pieces on a pottery wheel that is orientated the ‘right’ way up.

But, if the wheel is upside down, you have gravity on your side to help you pull the tall sides of the wall upwards.

Robert Compton Pottery

The History of the Pottery Wheel

Prior to the invention of the pottery wheel, most clay vessels were made by coiling and pinching the clay. Early potters would often hand-build their pots on a large leaf or mat and this would enable them to easily turn the pot as they worked.

Other potters would use a circular mold shape to support the base of their pot. Again, these simple molds allowed them to turn their potter as they built up the sides of the piece. (source: Blandino, B. 1984)

It’s thought that these simple bat-type bases eventually evolved into simple pivoted turntables. These could be turned by hand as the potter used their free hand to shape the pottery.

There is evidence of the first potter’s wheel around 5000BC in the Near East. Then during the Bronze and early Iron age use of the wheel spread across the Mediterranean and Europe. (source)

It’s thought that the potter’s wheel was introduced to the Americas by the Spanish around 1492. (source)

Initially, potters wheels were relatively slow. However, with the invention of the flywheel, the process of making pots on the wheel speeded up and fast wheels were invented. It’s thought that flywheels were first used to speed up pottery wheels before 2000 BC.

It’s amazing to think that thousands of years later many pottery wheels work using the same flywheel mechanism. Even if they are now mostly powered by electricity.

Final Thoughts

When you make pottery on the wheel it becomes like second nature. It struck me the other day that there was a time before the wheel had been invented. It’s funny to think that something that seems so natural is actually a skill that was invented by humans.

I hope you’ve found this whistle-stop look at the question ‘how does a pottery wheel work’ helpful. It’s a big topic, but I hope that this has given you the broad brush strokes. Happy potting.