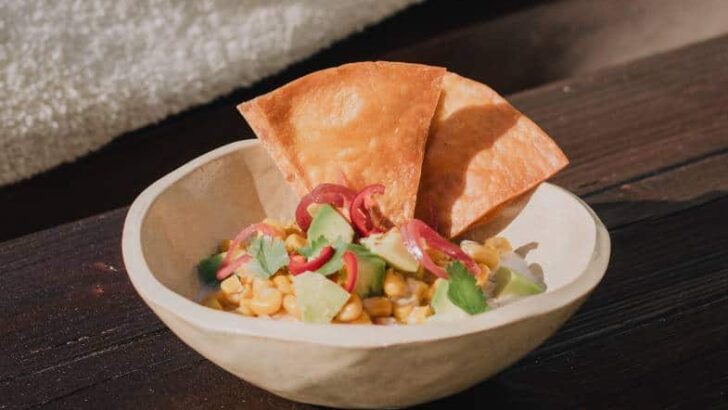

If you want to make pottery that you can eat off or drink from, you need to use food safe clay. The problem is that it can be confusing because there are a lot of different types and brands of clay available to purchase. This article looks at what types of clay are food safe and where you can buy them if you want to make your own dinnerware.

Food safe clay needs to be insoluble, non-porous, and non-toxic. The best clay to make pottery that will come into contact with food and drink is either stoneware clay or porcelain. It needs to be fired correctly and ideally glazed. Earthenware clay is also suitable if fired correctly, though it chips more easily than stoneware and porcelain.

However, there are other very popular types of clay such as air dry clay and polymer clay. You may want to know how these clays stack up when it comes to food safety.

I’m going to look at each of the following types of clay, in turn, to consider whether they are food safe or not. And if not, why not…

If you are especially interested in one particular type of clay, you can use the link above to jump to that section.

But, first, let’s take a brief look at what food safe clay is…

What is Food Safe Clay?

When you use pottery to eat and drink, you are putting the clay under some stress.

Firstly, the clay is coming into contact with liquid, acids, and alkalines in the food. Secondly, it is subject to being scraped by knives, forks, and spoons. And finally, the clay gets bumped and knocked when it is being used and washed.

In order to survive this kind of handling, food safe clay needs to have the following properties…

- It does not break down, weaken or disintegrate when it is in contact with food or liquid.

- The surface of the clay does not dissolve when it comes into contact with acids in the food or drink.

- The clay does not contaminate the food or drink with harmful metals or chemicals. This is known as leaching.

- It is non-porous, so it doesn’t absorb food and drink as it’s being used. And it doesn’t absorb water when it is being washed.

- The clay does not have a highly textured or crazed surface that can harbor bacteria and germs.

Whether you are planning to make some pottery for your own use or to sell it, it’s important that your clay meets these criteria.

In the next section, I will take a look at the different types of clay on the market, and consider which of these are actually food safe. So, read on…

What Type of Clay to Use for Food and Drink

The word ‘clay’ is used to refer to a wide range of materials with different properties. These substances look and feel very different to work with.

Here are some of the different kinds of clay that you might have heard of.

- Ceramic pottery clay (stoneware, earthenware, and porcelain)

- Paper clay

- Air dry clay

- Polymer clay

You’ll notice that ‘ceramic pottery clay’ contains three different types of clay. Before we look at these individually, here are some general features of pottery clay…

Ceramic Pottery Clay

Ceramic pottery clay is clay that needs to be fired in a kiln once the piece has been shaped and dried out.

Firing clay involves heating the pottery to very high temperatures ranging from 1832F to 2232F (1000-1222C). Sometimes potters fire their clay at temperatures as high as 2377F (1300C).

These temperatures can only be reached by a kiln that has been specially designed to fire clay. Pottery clay can’t be fired in a domestic oven, simply because it would not reach a high enough temperature.

It’s called ceramic clay because during the firing process the clay transforms from soluble clay to hard insoluble ceramic material.

So, once the clay has been fired, it can be submerged in water, and it won’t dissolve or disintegrate. Regardless of how long it is left in the water.

This gives pottery clay a definite advantage when it comes to being used to make dinnerware. Provided the clay has been fired correctly, it won’t crumble, lose its shape, or collapse when it’s in contact with water.

But does this mean it is a food safe clay? The answer is that it depends on what kind of ceramic clay you are using, and on how it is glazed. So, let’s take a closer look at what kind of pottery clay is food safe.

Food Safety and Different Types of Pottery Clay

There are three main types of pottery clay, and they are…

- Earthenware

- Stoneware

- Porcelain

Although there are other specialist types of clay, like raku clay, the three above are the main categories. There are lots of different brands of clay, within each category. However, they usually share some key features that are relevant to food safety.

Is Earthenware Clay Food Safe?

Provided it is fired correctly, earthenware clay can be food safe.

Before it goes into the kiln, pottery clay needs to be dried out completely. In its thoroughly dried state, it is called ‘bone dry’ greenware. Bone dry clay is very fragile, and the slightest bump can break it. In addition to this, if you put bone-dry clay in water, it will dissolve completely.

During the firing process, the clay particles move closer together, and the surface of the particles bond with one another. This process is called sintering.

Once the clay has sintered in the kiln, it has become ceramic. Because the particles are chemically bonded together, once the firing process is over, the pottery will no longer dissolve in water.

As a result, you can wash the pottery or fill it with liquid, and the clay won’t fall apart. However, in itself, this is not quite enough to make your pottery food safe.

Earthenware Clay is Porous

Part of the problem with earthenware clay is that even when it has been fired, it is still porous.

This is because although the bonded clay particles create a rigid permanent structure in the clay, there are still tiny open pores between the particles.

One of the reasons that earthenware is porous is that it is a low-fire clay. Low fire means that it is fired at the lower end of the temperature range.

It’s worth bearing in mind that the low fire range is usually somewhere between 1940-2109F (1060-1154C). So, these temperatures are still well in excess of those reached by a domestic oven. And even a low fire kiln will get exceptionally hot.

Nevertheless, in ceramic terms, earthenware clay is fired at lower temperatures.

When fired earthenware clay is submerged in water, the liquid will fill the open pores between the clay particles.

As well as being a potential harbor for bacteria open pores in earthenware can also weaken the clay in time.

Glazing Pottery for Food Safety

However, the solution to this issue is to glaze the pottery well. Glaze is the glass-like coating that you find on most, if not all, dinnerware, mugs, and cups. It serves to decorate the clay, but also to provide a waterproof seal on the pottery too.

The firing process for pottery normally happens in two stages. The first firing is called the bisque fire. This is when the pottery turns from clay to ceramic.

After the bisque fire, the pottery is coated with a liquid that contains ingredients that form glass when they are heated up. The liquid glaze quickly dries on the bisque pottery to form a powdery coating. This is then fired a second time.

During the second firing, the glaze melts to form a glass-like coating. As the kiln cools the glaze becomes solid and creates a glassy waterproof seal on the surface of the clay.

The waterproof glaze covers the porous earthenware clay, and creates a food safe surface.

Red Earthenware Clay – View on Blick

Some Words of Caution About Glazing

Although glazing pottery is a good way to create a waterproof barrier there are a few things to be aware of when it comes to food safety.

1) Not All Glazes Are Food Safe

Some glazes contain ingredients that are toxic to ingest. Whilst the majority of glazes are now lead-free, some still contain metals that make them unsuitable for dinnerware and mugs.

Glaze manufacturers are required to label glazes as either food safe or not food safe.

2) Some Areas of the Pottery Remain Unglazed

Because glaze melts when it’s fired, the part of the pottery that sits on the kiln shelf as it’s being fired does not get glazed.

If glaze were applied to the base of the pot, it would melt and stick to the kiln shelf during the firing. That is why the base, or at least the foot ring of a piece of pottery is normally unglazed.

Because earthenware clay is porous, it’s best to apply a suitable food safe glaze to as much of the pottery as you can. In particular, it’s important to glaze the areas that come into direct contact with food and drink.

But it’s a good idea to glaze the outsides of vessels like mugs too. This will seal as much of the pottery as possible and will reduce the amount of water that gets absorbed into the ceramic ware when it is being washed.

3) Glaze on Earthenware Can Weaken With Time

If the base of the pot is unglazed, then some water will be absorbed into the foot of the piece when it’s being cleaned.

For that reason, over time the unglazed base of earthenware pots can become discolored. But more importantly, when water is continually absorbed into an unglazed area of the pottery it can reduce the effectiveness of the glaze as a barrier.

Let’s say you wash your mug or bowl, and some water is absorbed into the unglazed areas of the pottery. If the vessel is then put straight into a microwave or oven, the absorbed water becomes hot.

If the oven becomes hot enough, the water will turn to steam. As it turns to steam it expands and puts pressure on the ceramic ware. In some cases, this can cause the pottery to crack. Cracks and crazing in the glaze surface are potential hazards because bacteria can build up in these crevices.

But, as absorbed water heats up in the pottery it can also cause the glaze to start separating away from the clay. When the glaze starts to flake, chip, or separate from the clay, it stops providing a food safe seal on the pottery surface.

4) Earthenware Clay is Fragile

Earthenware becomes hard ceramic when it’s fired, however, it is still a relatively fragile form of ceramic ware. Because it is porous, it chips and scratches quite easily. This damage to the clay and glaze can be a point of entry for food and water into the pottery.

So, although earthenware clay can be used to make functional pottery, it does need to be treated with some care to keep it food safe.

Another option is to make your pottery out of stoneware clay. Stoneware is stronger and is less likely to chip and break with the knocks and bumps that dinnerware goes through when it’s being used and cleaned. For that reason, it’s a more reliable food safe clay than earthenware clay. So, let’s take a closer look at stoneware clay now.

Is Stoneware Clay Food Safe?

Like earthenware clay, if it is fired correctly, stoneware clay is food safe. However, stoneware clay has a few advantages over earthenware that make it an even better option for pottery that will be used with food and drink.

One of the main differences between earthenware and stoneware is what happens to the clay when it is fired. Stoneware clay contains substances called glass formers. When stoneware clay is fired, these components melt in the heat of the kiln to form a liquid glass within the clay.

The molten glass fills up the pores between the clay particles. When the kiln cools the glass turns solid in the pores. This process is called vitrification.

The result is that fired stoneware clay is much less porous than earthenware. Clay manufacturers refer to the porosity of clay as the absorption rate. This is what percentage of the clay’s body weight it will absorb when submerged in water.

Normally stoneware clay has an absorption rate of between 1 and 2%, though this can be higher depending on the type of stoneware clay being used.

Amaco Buff Stoneware Clay – View on Blick

Some of the Benefits of Stoneware

Stoneware clay is typically seen as a good option for functional pottery such as dinnerware and mugs. Here are some of the reasons why…

- It is strong and ‘stone-like’. Because stoneware clay is denser and less porous, it is stronger than earthenware and less prone to chipping.

- Stoneware clay is a mid to high fire clay. This means that it is fired at temperatures ranging from 2185F (1196C) to 2381F (1300C). At these temperatures, some ingredients in the clay melt. The molten elements in the clay mingle with the glaze in its melted state.

This mingled layer of clay and the glaze creates a strong bond between the clay body and the glaze. Not only does this create a food safe barrier, but it makes the glaze less likely to chip and flake off when the pottery is being used. - Another advantage to being less porous is that it’s not completely necessary to glaze the pottery all over. It’s recommended that you glaze all the surfaces that come into direct contact with food and drink.

However, with stoneware clay, you can leave areas that are not in direct contact with food unglazed. For example, you may choose to leave areas on the outside of a mug unglazed. This can look lovely, particularly if you are using an especially attractive clay, like speckled stoneware.

Some Words of Caution About Stoneware

The upshot of the above is that stoneware is a good food safe clay. However, when food safety is concerned, it’s always good to err on the side of caution. So, here are some things to be aware of when making pottery from stoneware clay…

1) Porosity

Although stoneware clay is less porous than earthenware clay, some stoneware clays are more porous than others. When you buy clay, the seller or the manufacturer will state how porous the clay will be once fired. If you are planning to leave areas of the dinnerware unglazed, it’s best to get less porous stoneware.

2) Correct Firing

Although stoneware clay and glazes can be food safe, they do need to be fired at the right temperature. If the kiln does not reach a high enough temperature, the clay won’t mature and it will stay porous.

Similarly, problems can arise if clay is overfired. It can become hard and brittle rather than strong and dense.

3) Problems with Glazing

If you have tried glazing pottery, you will realize that it’s an art and a science all of its own.

For example, not all clay bodies and glazes play nicely together. Some glazes just don’t ‘fit’ the clay well. If there is a lack of fit between clay and glaze, the glaze can be under a lot of tension.

This can cause the glaze to craze, or flake off. When glaze flakes of fired pottery, this is called ‘shivering’.

Other issues can arise with glazing such as crawling, where the glaze literally crawls away from areas of clay.

Or you might encounter pin-holing, where small holes appear in the surface of the glaze and reach all the way down to the clay body.

Needless to say, all of these issues with glazes affect the ability of the glaze to create an effective food safe barrier.

Is Porcelain Clay Food Safe?

Like stoneware clay, porcelain is a mid to high-fire clay, which means it is fired at higher temperatures than earthenware clay.

And like stoneware, when it’s fired, the pores between the clay particles fill up with molten glass and the clay becomes very dense.

In fact, when porcelain has been fired, it is even less porous than stoneware clay. Whilst stoneware usually has an absorption rate of 1-2%, porcelain has an absorption rate of just 0 to 1%.

2381F (1300C) is generally the hottest temperature potters will fire clay at. Some types of porcelain, when fired at these very high temperatures will have a 0% absorption rate. This means that they are absolutely impermeable.

In addition to having such low porosity, porcelain is extremely dense and hard. Each of these qualities makes porcelain a great option for dinnerware. As such, if it is fired to the right temperature, porcelain is most certainly a food safe clay.

Do You Need to Glaze Porcelain to Make it Food Safe?

When it’s been fired, porcelain often has a glassy smooth finish and very low porosity. With such a low absorption rate, sometimes having zero porosity, you may be wondering if it’s necessary to glaze porcelain to make it food safe.

The answer to that question depends on whom you ask. Some potters who use porcelain prefer to glaze it. This is because unglazed pottery can be harder to clean.

Even with very low porosity, unglazed clay can have nooks, crannies, and textures that are hard to clean. By contrast, glaze will fill in and smooth over those textures, making it harder for food to lurk and harbor bacteria.

As a result, potters often use a liner glaze, at least on the areas that come into direct contact with food and drink.

In addition to this, unglazed clay will be more prone to staining from highly colored food and drink like tea, coffee, and berries. A glaze can prevent porcelain from becoming discolored.

However, not all potters glaze all porcelain, and an unglazed porcelain surface can have a beautiful, organic velvet-like finish.

Porcelain Clay – View on Blick

Is Paper Clay Food Safe?

There are two types of clay that go by the name of paper clay, one is called ‘Paperclay’ and the other is ‘Paper Clay’. And if you are considering food safety, it’s important to know how they differ.

Cellulain Porcelain Paper Clay – View on Blick

‘Paperclay’, is a kind of air dry clay that doesn’t need to be fired in the kiln. An example of this is Creative Paperclay which contains cellulose fibers (source). These are fibers that are made from plants and vegetation.

It is the cellulose fibers, rather than the firing process that gives Paperclay its strength. When the clay dries out, the fibers harden and create a rigid structure in the clay which give it some internal support.

Paperclay of this sort is not food safe. Whilst it has some strength in its dried form, if it gets wet it will start to break down. If the Paperclay is submerged in water it will eventually dissolve completely. But even if it makes contact with moist food, the surface will begin to disintegrate and particles of clay will contaminate the food.

I will say more about air dry clay later, but for now, let’s take a look at Paper Clay.

What is Paper Clay?

Paper Clay is ceramic clay that does need to be fired in a kiln to become ceramic. Similar to Creative Paperclay, it also contains fibers to strengthen it. These fibers can be made from paper, wood, flax, cotton, or cellulose.

However, when paper clay is fired, the fibers burn out of the clay. Whilst the fired ceramic clay remains, the burned-out pulp leaves holes and channels running through the fired clay body. Although the resulting fired ceramic work is lightweight and insoluble, it is porous.

But is paper clay food safe? The answer to this is that it depends on where you get it. If you buy commercially made paper clay, it will have a relatively high fiber content. This means that the fired pottery will be very porous. For example, paper clay that you buy from a pottery supplier will sometimes have a porosity of around 17%.

Although you could try to seal paper clay with a perfect liner glaze, most glazes do not offer 100% coverage. There are often small imperfections, pinholes, or cracks that will allow moisture to seep through.

However, if you make your own paper clay, then you have control over how much fiber is added, and the porosity does not need to be so high. An example of a potter who makes functional work from paper clay is Jerry Bennett.

He makes his own paper clay by adding around 3 ounces of fiber to 25lbs of clay powder, then mixing them with water. By controlling the amount of fiber added to the mix he is able to make food safe clay. He hand-builds really beautiful teapots and cups from his paper clay.

Porcelaine Paper Clay – View on Blick

How to Test The Porosity of Your Clay

If you want to make your own paper clay there are ways that you can test its porosity.

Here are three simple ways to check whether your clay is absorbing liquid…

First Method:

Fill your vessel with water. Then position it on a sheet of paper and leave it overnight. If water is passing through the wall of your ceramic ware, there will be a damp patch on the paper where the pot was sitting.

Second Method:

Put some drops of die on your clay, something like Indian ink works well. Let the ink soak in for a while. Then wash the clay underwater. The darker the ink stain the more ink has been absorbed.

Third Method:

However, the following method is a more accurate measure of absorbency…

Take a small sample of your fired clay and weigh it in its dried state. Then let the clay soak in water for 24 hours. Remove the clay from the water, dry it and weigh it again.

Subtract the weight of the dry clay from the weight of the clay once it has been soaked in water. This will give you the weight of the water that has been absorbed.

For example, if the original weight of your dry clay is 5g, and the soaked clay is 5.2g, then the clay absorbed 0.2g of water.

Divide the weight of the water by the weight of the dry clay. In the above example, you would divide 0.2 by 5, which equals 0.1.

You then move the decimal point two places to the right giving you an absorbency rate of 4% (source).

Is Air Dry Clay Food Safe?

There are lots of different brands of air dry clay and each of them has its own unique qualities. Some of them can only be air-dried. Others can be air-dried or fired in the kiln.

However, what they have in common is that if they are air-dried they are not food safe. There are a few reasons for this. The first reason, mentioned earlier, is that air dry clay is not waterproof.

When air dry clay comes into contact with water it starts to disintegrate. If air-dry clay comes into contact with wet food, the surface will start to break down and particles of clay will mix in with the food or drink. And if it is emersed in water, the item is likely to dissolve completely in the long run.

Crayola Air Dry Clay – View on Blick

Can You Seal Air Dry Clay to Make it Food Safe?

The answer to this question is unfortunately no. There are a couple of reasons why sealants do not make air-dry clay food safe.

The first reason is that most sealants are not 100% watertight when applied to air-dry clay. With time, most sealants will start to break down and moisture will start to seep through to the underlying clay body.

The second reason is that whilst many sealants are labeled non-toxic, this is not the same as being food safe. A food safe sealant needs to be stable enough so that it won’t break down when it is being used or washed.

While sealants like ModPodge are non-toxic, they may lose their integrity through everyday use. As such, the sealant itself or the underlying air dry clay may end up being ingested.

It’s usually recommended that sealants like ModPodge are applied to parts of the piece that are not coming into direct contact with food or mouths.

This is the case even if you are intending to use the air-dry pottery for dry food like popcorn or chips. Although this may seem overly cautious, it’s because there is no guarantee that the sealant won’t flake off and mix in with the food.

Nevertheless, it does have the huge advantage of not needing to be fired in a kiln. So, if you are making projects that are not going to come into contact with food or liquids, and you don’t have access to a kiln, air dry clay is a great option.

Crayola Air Dry Clay – View on Blick

Is Polymer Clay Food Safe?

Ceramic clay contains natural clay minerals that have been mined from the ground and processed. By contrast, polymer clay doesn’t contain natural clay particles. Instead, it is made mainly from PVC (Polyvinyl Chloride) combined with plasticizers, fillers, and colorants.

As such polymer clay is a very different kind of material from pottery clay. There are lots of different brands of polymer clay such as Sculpey and Fimo amongst others. Each of these brands will offer its own safety instructions regarding using its products.

However, what they all have in common is that polymer clay is not classified as being a food safe clay.

Why is Polymer Clay Not Food Safe?

In the past, there has been some controversy over whether polymer clay was toxic or not. An article was published by PIRG in 2002 which stated that polymer clay contained potentially harmful ingredients called phthalate plasticizers.

However, since it’s publication most brands of polymer clay have stopped using dangerous phthalates in their products. In fact, many brands, including Sculpey, are phthalate free (source).

Furthermore, polymer clay is currently certified by the ACMI (Art and Creative Materials Institute) as non-toxic.

Nevertheless, there are a few things about polymer clay that mean it is not food safe. Here are a few of those features…

1) Polymer Clay is Porous

You might find some articles stating that polymer clay is non-porous once it has been cured in the oven. However, the manufacturers of Sculpey advise that it is porous. They state that ‘cured polymer clay is porous. If you try to use a finished creation as a food utensil, it won’t be easy to clean sufficiently’ (source).

So, whilst polymer clay is waterproof and won’t dissolve in water like air dry clay, it is not 100% watertight (source).

2) Polymer Clay Can Be Brittle

Polymer clay is baked in a regular domestic oven. When it’s baked at the right temperature for the right length of time, it is durable. As such it can make long-lasting decorative items, like jewelry, figurines, and keepsakes.

However, it wouldn’t withstand the rigors of being used for food and drink. For example, if it was washed regularly in a dishwasher, polymer clay would become brittle and prone to breaking.

Because it can become unstable after being exposed repeatedly to heat and moisture, there is a possibility that fragments of the polymer clay may contaminate food and drink.

Most manufacturers of polymer clay state that it can be used to decorate areas that don’t come into direct contact with food and drink. A good example would be the handles of cutlery or the outside of a mug or drinking glasses.

Final Thoughts

For food safety, your best option is either stoneware or porcelain. However, this needs to be fired correctly, and by that I mean it shouldn’t be over or underfired, as this will affect its strength and integrity.

Earthenware is also a good option, though it does need to be glazed well on any surfaces that come into direct contact with food.

Modeling clays like air dry clay and polymer clay are not food safe. Commercially-made Paper clay is also not food safe. However, if you are interested in making your own clay, you could adjust the ingredients to create your own food safe clay body.