You may have noticed that some clay bodies contain something called grog. But what is grog in clay and why is it important when we make pottery?

Grog is a gritty material that gives the clay strength which can make it easier to throw and hand build. It reduces clay shrinkage and cracking which makes firing easier, and it adds texture to the pottery too. There is a range of grogs, from fine to coarse.

What is Grog In Ceramics? – An Overview

Grog is made from several materials that have been fired and then ground up. It can be made from a ceramic material that has been fired specifically to be made into grog. Or it can be made from waste pottery that is broken by accident and recycled by making it into grog.

It can also be made from ground-up brick and other refractory rock. ‘Refractory’ just means that the material won’t melt and can survive high temperatures.

Grog can be added to almost all types of clay. The type of clay that is being used will determine the type of grog that is suitable. Grog can be categorized in a couple of ways.

Soft and Hard Grog

Firstly, grog is categorized as being soft or hard. Generally, grog is made from material that has been fired before. If it has been fired to a high temperature, above cone 10, then it is classified as hard grog. But, if it has been fired to below cone 10 it is considered to be soft grog.

Soft grog is often used because it is porous and will reduce stickiness in a clay body. However, because it has only been fired up to cone 10, the grog can melt if the piece of pottery is fired above cone 10.

Hard grog is made of ceramic material that has been fired above cone 10. This means it is more robust. Because it is fully mature, it is unlikely to melt before the piece of pottery is completely fired. For this reason, hard grog is more often used than soft grog.

Grog and Mesh Size

Grog comes in different-sized granules. Some fine grogs look like powder. Other grogs with larger particles look like grains of sugar.

Grog is graded according to a ‘mesh’ system. This system refers to the number of holes per inch in a piece of mesh. So, for example, ’48 mesh’ refers to a piece of mesh that has 48 holes per inch. The more holes there are in a mesh, the smaller the holes need to be.

Grog can be given a single mesh number. For example, it may be classified as a ‘150-mesh grog’. This means that the grains of grog are small enough to pass through a 150-mesh sieve. Grog that is 150 mesh consists of grains that size and smaller.

Mesh can also be classified according to its range. For example, a mesh might be referred to as a 20/40 mesh. This means that grains of grog would be small enough to fit through mesh with 20 holes per inch. And they would be too large to fit through mesh with 40 holes in it.

The range system is useful because it lets the potter know what the smallest and largest grain will be. This gives them more control over the properties the grog introduces to the clay.

By contrast, if the grog has a single mesh number, the grains may be anything up to the mesh size specified. A 30/80 mesh grog suits the purposes of most pieces of pottery.

Are All Grogs Equal?

It is not always possible to predict the effect that grog will have on clay. This is because there can be big variations even with the mesh range system. Grog made by different companies, with the same range can be quite different.

One manufacturer may include more particles at the larger end of the scale. Another manufacturer may include finer particles within the range.

This means two grogs with the same range of grading may affect the pottery differently. So it is a good idea to experiment with the effect that a particular grog has on your pottery.

What is Grog In Pottery? – The Ingredients

All clays contain alumina and silica in different amounts. Grog contains a high percentage of both. Alumina and silica give grog important properties.

Alumina has a high melting point. It also has a high mechanical strength and can tolerate a lot of wear and tear (source).

Silica is one of the glass-forming materials in clay and glazes. But silica also plays an important role in giving the clay structure.

Clay components attach themselves to silica. This improves the structural integrity of the clay and makes it stronger. Silica also helps to regulate how much pottery shrinks when it dries, and when it is fired.

What is in Grog?

The table below gives you an idea of the main ingredients in grog and their quantities.

| Alumina | Silica | Iron Oxide | Calcium Oxide & Magnesium |

|---|---|---|---|

| Min 40% | Min 30% | Max 4% | Up to 2% |

Why is Grog Added To Clay?

Grog in ceramics is used as a ‘temper’. You may hear the term ‘grog tempered clay’. A temper is a non-plastic material that can give the clay the following properties…

- Reduce the shrinkage of your clay

- Help prevent cracking

- Make clay more workable and hold its shape

- Add texture to your pottery

Let’s have a closer look at each of those items…

Reason 1) Grog Reduces Shrinkage in Pottery

Grog reduces how much clay shrinks as it dries out and also as it is fired. The more grog added to the clay body, the less it will shrink.

It shrinks less when it dries out before going into the kiln because the grog particles have already been fired. As a result, they have a lower water content in the first place. So, they lose less volume as the clay dries.

Also, when ungrogged clay dries out the particles move closer and the distance between them reduces. By contrast, particles of grog produce a porous matrix that does not shrink as much

Grog also enables clay to dry more evenly because of its porosity. The open spaces between the particles allow water to move to the surface and evaporate more readily.

When a piece of pottery is fired, it shrinks for a few reasons. One reason is that it loses more water. But it also loses volume because of vitrification. At a certain temperature, the silica in the clay will interact with other ingredients and form liquid glass.

The glass-forming substances leave the clay particles and fill up the gaps between the particles. This causes a bit of shrinkage. Because the grog has already been fired to maturity, it does not melt.

If the kiln becomes hotter than the temperature at which the grog was originally fired, the grog will melt. The melting point of grog is normally around 3240F (1780c), which is much hotter than cone 10. You can read more about cones and firing temperatures here.

Reason 2) Grog Helps Prevent Cracking in Pottery

One of the main reasons that clay cracks is that the clay body is stressed when it shrinks. By reducing the amount that the clay shrinks, the grog also reduces the chance that the pottery will crack.

In addition to this, grog reduces thermal expansion. When pottery heats up in the kiln, it expands. The expansion is only a tiny amount, but because the ceramic is brittle at this point, a tiny expansion can cause it to crack.

However, grog has already been fired and gone through the process of expanding in heat. Therefore, it reduces the amount the pottery expands and reduces the chance of cracks occurring.

Reason 3) Grog Makes Clay More Workable

It is sometimes said that grog makes clay more workable because it improves the clay’s plasticity. However, plasticity is the clay’s ability to be stretched, worked, and pulled into shape without cracking.

Grog, on the other hand, is a bit like internal scaffolding in the clay that stops it from slumping. It adds structural strength.

One comparison that helps me to visualize the role of grog in clay is that of wattle and daub. Do you remember learning about wattle and daub in high school? From as far back as the Stone Age, buildings have been made from wattle and daub.

Mud is mixed with straw and other debris and then pressed between wooden battens to make walls. The straw is added to the mud to give the mud strength and to stop it from slumping.

Although it is not an exact comparison, grog acts a little like wattle and daub. A clay particle is usually around 10,000 mesh in size. By contrast, a medium-sized grog is 20-48 mesh (source). So, grog particles are huge compared to clay particles. If you bear this in mind, it is a bit like adding a handful of straw and debris to mud.

Reason 4) Grog Reduces Clay Plasticity

Although grog makes clay more workable, it reduces plasticity. Plastic clay is stretchy and bendy. However, if you add grit to a substance, it will make it more grainy and less stretchy.

In fact, the finer the grog the more it reduces plasticity. The larger the grains of grog, the more it prevents shrinkage, and the less it reduces plasticity.

This suggests that larger-grained grog is better. However, grog does affect the look of pottery, so you have to bear in mind what you want your pots to look like.

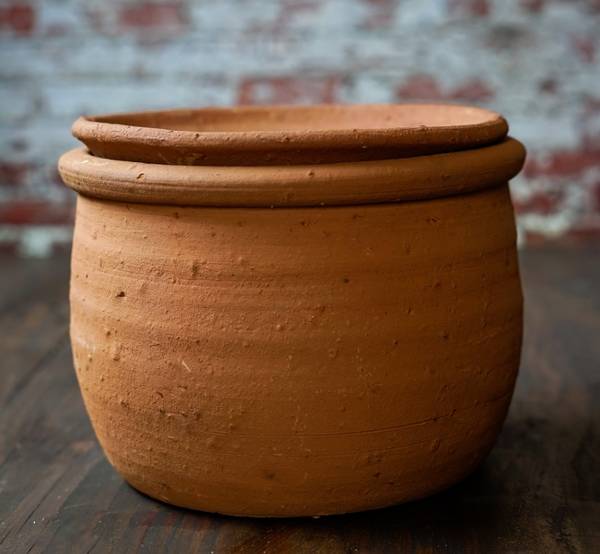

Reason 5) Grog Adds Texture to Pottery

Adding grog to clay can give it a gritty texture. This texture is sometimes called ‘tooth’. and grog pottery is often said to have a ‘toothy’ quality.

All clays have grog in them, and some clays naturally have more grog. For example, unlike porcelain, earthenware, can be a naturally groggy clay.

On the other hand, grog can be added to porcelain. Most grogs have a high iron content and are not used in porcelain. This is because the iron affects the white color of the porcelain.

However, a substance called Molochite can be used as a grog in porcelain. Molochite is made of kaolin, a white clay, that has been fired at a high temperature. It is a clean pottery grog with a fine mesh of 120. Also, it is glassy and white when fired, so it does not affect the smooth texture of porcelain.

You can compare the ingredients of Molochite below, with those of standard grog above.

What is in Molochite?

| Alumina | Silica | Iron Oxide | Potassium | Titanium |

|---|---|---|---|---|

| 42% | 54.50% | 1% | 2% | 0.07% |

Because most clay with grog has a gritty texture, it can feel rough on the hands when the clay is thrown on a wheel. Whilst this might feel like a chance to get a free exfoliation, it can be tough on the skin in the long run. However, if a 20-40 mesh grog is added to a plastic clay body, the resulting mix can feel quite smooth.

Final Thoughts

Clay grog is versatile. It can give you that rough textured rustic look. However, there is a large range of types of grog. Finer grogs give you the benefit of reduced shrinkage and cracking without losing your smooth finish.

Grog is a way of tempering your pottery clay and giving your ceramics the best chance of surviving in the kiln. You can buy clay that already contains grog. Or you can add grog to your own clay. Adding grog to clay can be a fun experiment and can give you the freedom to create grog clay with the texture and look that you like.

In addition to this, you can buy grog for clay from most pottery suppliers. You can add this to your favorite clay body by wedging it in. Alternatively, you can make your own ceramic grog out of pottery that has already been fired. But that’s an article for another day!