Your cart is currently empty!

What is Flashing in Ceramics – And How is it Done?

Published:

Last Updated:

Affiliate Disclaimer

As an affiliate, we may earn a commission from qualifying purchases. We get commissions for purchases made through links on this website from Amazon and other third parties.

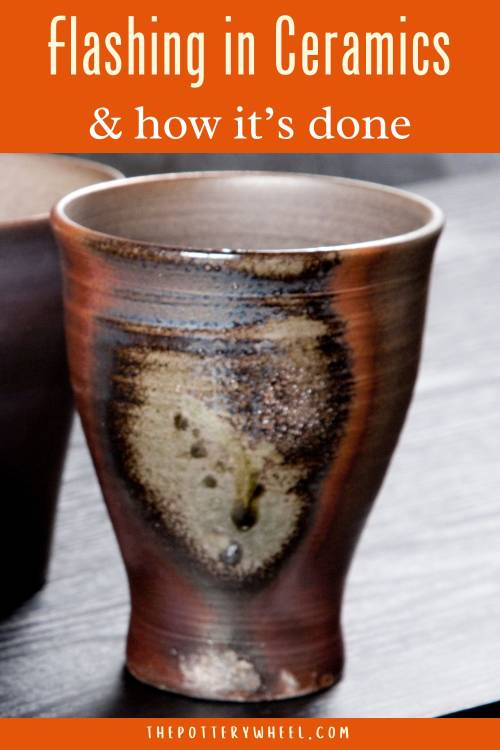

Have you ever seen pottery that has been fired in a fuel-burning kiln and noticed the beautiful, irregular colors and tones? These mysterious swirls and daubs are sometimes called flashing effects.

“Flashing” refers to changes in the color, pattern, and texture of pottery. It occurs naturally during firing when clay comes into contact with flame, wood ash, or soda vapors. It is also a sought-after decorative effect and can be achieved in modern kilns by using flashing slips.

Flashing And Wood Fired Ceramics

Flashing is typically associated with fuel-burning kilns. In particular wood fired pottery. The reason for this is that during a wood firing, the flame travels around the kiln in particular pathways. If you think about a fire sliding up a chimney, it tends to stick to the same pathway.

During a wood firing, the pottery comes into direct contact with the flame. Because of the paths that the fire travels, some parts of the pottery have more contact than others.

The flame will deposit more ash on some parts of the pottery than others. This partly accounts for the flashing effect of wood-fired ceramics.

(CC BY-ND 2.0)

As trees grow, they draw up minerals from the ground. Wood has a high mineral content (source). These minerals are released as the wood burns and are transported around the kiln by the flame.

Wood ash created during a firing contains trace metals from the burning wood. This ash settles on the pottery and melts, creating a glaze.

Many of the minerals in wood are the same as the minerals used in pottery glazes.

The kind of effect that is created depends on the type of wood being burned. Different types of wood have different mineral contents. And these look different when they melt.

The appearance of flashing also depends on the type of clay being used. Different clay bodies contain different proportions of minerals. These minerals interact differently with wood ash. You can find out more about wood firing in my article about different methods of firing pottery here.

Flashing and Soda Firing Ceramics

The random color and texture of flashing patterns are created by elements interacting with the pottery. Some parts of a piece are more exposed to elements such as flame and ash.

Another way to create this effect is to introduce additional substances to the atmosphere of the kiln. This is the principle behind soda firing and soda-fired pottery A sodium carbonate mixture, suspended in water is sprayed into the kiln during the firing.

When the sodium meets the flame it vaporizes and is carried through the kiln. The sodium lands on the pottery and interacts with the clay surface to create a glaze. It is interacting with the alumina, silica, and other minerals in the clay. Therefore, different clay bodies with different mineral content will interact to create different glaze effects.

The soda mixture is usually sprayed into the kiln via ports (openings) on the side of the kiln. Certain parts of the pottery will be more directly in line with the sprayed mixture.

This creates variations in the appearance of the soda glaze on each piece. One side of a piece may be glossy, whilst the other side may be a different color and texture. It is this variation that creates the flashing effect.

Salt Firing

Salt firing is an older version of soda firing. An important difference between salt and soda firing is what happens when the mixture vaporizes.

When salt meets flame it creates sodium and chlorine. The chlorine leaves the kiln in its gas form through the kiln chimney. More recently, releasing chlorine into the atmosphere has been recognized as an environmental hazard. This is why salt glazing isn’t done on an industrial scale anymore.

By contrast, vaporized soda creates carbon dioxide rather than chlorinated gas. As a result, it is thought to be less harmful to the environment.

Another difference between salt and soda firing is the resulting glaze. Soda firing generally creates a more refined finish than salt firing.

A salt firing tends to have strongly defined patterns and an ‘orange peel’ texture. By contrast, though soda firing also creates dramatic texture and color variations, the overall effect is a bit more subtle. You can read all about this technique in a complete guide to salt glazing here.

What are Flashing Slips in Ceramics?

Some potters are passionately committed to more labor-intensive kinds of firing like wood firing or pit firing. These techniques are very elemental and unpredictable. It is this variability that creates the flashing effect. Flashing was originally the incidental result of the firing techniques used.

However, most modern firing techniques create a more stable, controllable kiln environment. Flashing is not the natural byproduct of modern kilns.

But flashing can be extremely beautiful and lots of potters want to recreate the look without spending 3 days stoking a wood-burning kiln! One way to achieve flashing in a modern kiln is a ‘flashing slip’.

Flashing slips contain high levels of alumina. Alumina is a metal element that reacts during firing to create a flashing effect. Most flashing slips contain a lot of kaolin because kaolin has a high alumina content. Potters will often create their own flashing slip recipes.

Here is an example of a simple flashing slip recipe:

Grolleg Flashing Slip

- Grolleg Kaolin 60%

- Nepheline Syenite 40%

Are Flashing Slips Applied to Greenware or Bisque Pottery?

On the whole flashing slips are used on unfired clay. The reason for this is that slip is mostly made out of unfired clay.

Mixing unfired clay with bisque ware often does not work. Clay shrinks during its first firing. As a result, slip applied to fired clay shrinks more than the bisque pottery. As the slip shrinks, it cracks and flakes off the bisqueware.

However, some potters do apply flashing slips to bisqueware. One suggestion when applying flashing slips to bisqueware is to make sure the slip is thin. It normally has the consistency of skim milk. If it’s thicker then it tends to flake off.

Another suggestion is to adapt the ingredients. Some potters use a proportion of calcined kaolin in the slip. Calcined kaolin has already been bisque fired. So, it shrinks less than raw kaolin and behaves more like the bisqueware it’s been applied to.

What Kind of Kiln Can a Flashing Slip Be Used In?

Generally, flashing slips are used in fuel-burning kilns rather than electric kilns. The reason for this is that flashing requires a reduction atmosphere to occur. Electric kilns are not used in reduction firing.

A reduction environment happens when there is a deficit of oxygen present in the kiln. A limited supply of oxygen in the kiln means that the fuel does not burn completely. The atmosphere becomes saturated with gases and smoke. This atmosphere contributes to the occurrence of flashing.

Final Thoughts

Flashing effects range from the big and bold to the delicate and subtle. Either way, flashing can be beautiful and surprising.