Your cart is currently empty!

The History of Delft Pottery – Delft Blue Over the Years

Published:

Last Updated:

Affiliate Disclaimer

As an affiliate, we may earn a commission from qualifying purchases. We get commissions for purchases made through links on this website from Amazon and other third parties.

Dutch Delft pottery has been made for hundreds of years. And the history of Delft pottery is an intriguing story that stretches back to the 16th century. This article is an overview of the fascinating journey that Delftware has made from centuries ago to the production of Delft today.

The History of Delft Pottery

Dutch Delft pottery is often referred to using various terms. These include Delftware, Delft Blue pottery, Delft Blue or Delft Blauw.

Delftware is often called Delft Blue because it is often decorated with cobalt oxide, which creates blue designs on the pottery surface.

Although some Delftware is decorated with other colors like orange, yellow, red-brown, green, and gold, it is usually associated with iconic blue patterns.

The Very Early History of Delft Pottery

The pottery that you would recognize today as being Delft blue first started being made in the early 17th century.

However, pottery was made in the Netherlands for hundreds of years before that. As far back as the early 15th century, Dutch potters were making simple earthenware pottery.

Potteries were located in areas where clay could be sourced easily and locally. The clay was red or brown earthenware and the pottery was decorated using colorful clay slip.

The Early Glazing Process

Once decorated the pottery was glazed using a clear lead glaze. These pieces were stacked on top of one another and fired upside down in a kiln. The kilns were heated with wood and peat.

Before it was fired in a kiln, the liquid glaze is applied to the pottery. The glaze was made up of materials such as quartz suspended in water.

Lead oxide was added to the liquid glaze. The lead helped lower the temperature at which the glass-forming materials in the glaze would melt.

During firing the lead glaze melted over the surface of the pottery. As the kiln cooled the molten glaze would form a solid glossy, transparent glass coat on the ceramics.

If the pieces of pottery had been stacked directly on top of each other, the lead glaze would have welded the individual pieces together.

To avoid this, the pottery was separated using spurs. These spurs were triangular pieces of ceramic material with three small points that made contact with the pottery.

The spurs were a bit like flattened tripods that sat between the pottery in the kiln keeping the glazed pieces from touching one another. They look a little bit like what we call kiln stilts today.

Midnight Blue – Simone van der Vlugt

If you want to read a good novel about the history of Delft pottery, I’d recommend a book called Midnight Blue.

It’s well researched and it brings the era to life. I listened to it on Audible and enjoyed it a lot.

Features of Early Dutch Pottery

The spurs stopped the pieces from welding together completely. However, after firing, the spurs had to be removed from the pottery. They left three small scars on the pottery glaze where the points had been in contact with the glaze.

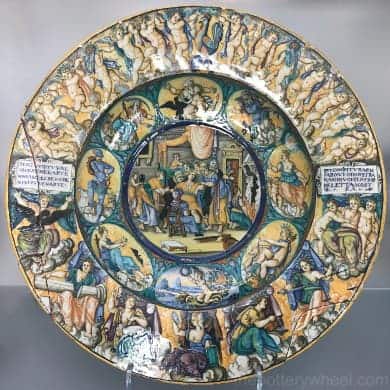

You can see these small scars on the glaze below on this example of early Dutch earthenware. There are three points on in the middle of the plate where the spurs were in contact with the plate whilst it was being fired. The most visible spur mark is just above the cherub’s left hand.

Image courtesy of Rijksmuseum. (Public Domain)

In addition to these small marks on the glaze, the underside of the pieces was darkened by the firing process. This is because the pottery was fired upside down. The ash and dirt in the wood-fired kiln would fall onto the underside of the pottery during firing.

Early Italian Pottery

During the same period of time in the early 15th century, southern-European potters in Italy and Spain had developed a style of pottery ware called Maiolica.

Italian Maiolica was tin-glazed. Tin glaze was a lead glaze that contained a small quantity of tin oxide. The tin oxide created a shiny white opaque finish that covered the locally sourced clays which varied in color. Tin-glazed earthenware is often called ‘faience’.

After the pottery had been formed, the clay was fired for the first time. This is called the bisque fire. The bisque-fired pottery was then coated with the tin glaze.

The tin glaze creates a white background. Decorations would be painted on top of the unfired tin glaze. These decorations were painted using ceramic pigments.

The range of colors available changed over the centuries. By the 16th century, a wide range of colors was available allowing the potters to create beautiful decorations.

Here are two examples of different styles of Italian tin glazed earthenware.

1600-50, tin-glazed earthenware. Located at the V&A.

About 1545, tin-glazed earthenware. Located at the V&A.

In addition to creating a white background, the tin glaze was unlikely to run when it was being fired. This meant that the decoration painted on top of the glaze would not blur in the kiln.

Initially, the Italian potters applied the tin glaze to the pottery and applied the decoration on top of that. After that, the pot was fired for a second time. However, later in the 16th century, they started to apply a second clear glaze on top of the painted decoration too. This gave the maiolica a brilliantly shiny finish (source).

The Italian Firing Process

Italian potters had also developed a way of firing the pottery that would protect it from the ash and smoke of the wood-fired kiln.

The pottery was placed in ceramic containers called saggars. The pots were fired for a second time to melt the glaze. During the glaze or ‘glost’ firing, the white glaze and decoration on the pottery were protected from the dirt in the kiln by the saggars.

By using saggars the Italian potters were able to create brilliant white clean pottery with refined decoration.

The Italian Influence on Delft Pottery

In the 16th century, some Italian potters relocated and settled in Antwerp. They brought with them their pottery skills and tin-glazing techniques.

The Italian method of making maiolica was adopted by the local potters in Antwerp. As a result, white tin-glazed maiolica started to be produced in the neighboring Netherlands too, and became very popular amongst the wealthier households.

However, in time, many of these potters moved from Antwerp in the south to the northern cities of Delft and Haarlem in the Netherlands. This was in part because the north was thriving economically. But also, many of the potters were protestant, and they were less likely to encounter religious persecution in the north.

As a result, pottery production declined in Antwerp and grew in Haarlem and Delft. This was a significant turning point in the history of delft pottery. And at the beginning of the 17th, Delft had eight potteries, that produced “fairly simple maiolica.”(1)

The Chinese Influence on Delft Pottery

At this time the Chinese were making very refined porcelain ceramics. A very limited number of Chinese porcelain pieces were imported into Europe and were usually owned by the very wealthy.

However, a few developments in the 17th century increased the amount of Chinese porcelain in circulation in the Netherlands.

- Two large Portuguese cargo ships laden with Chinese porcelain ware were captured by the Dutch. This large amount of Chinese porcelain entered the Dutch market and was very popular.

- In addition to this, the VOC was formed. The VOC (Dutch East India Company) was a trading company founded in 1602. It was set up to enable long-distance trade between Asia and Europe.

The formation of the VOC enabled large amounts of Chinese porcelain to be exported to the Dutch Republic (now called the Netherlands) (source).

Delft was one of the seats of the VOC. As a result, a large quantity of imported Chinese ware became available in the city of Delft.

via Wikimedia Commons

The popularity of Chinese porcelain was a threat to the livelihood of the Dutch potters who were still making maiolica. Some of the Dutch potteries closed down, but others began to make imitations of imported Chinese porcelain.

At the time, porcelain clay had not yet been created in Europe. The first European porcelain factory was built about 100 years later in 1710 in Germany. So, it was hard for the Dutch potters to imitate the Chinese ware which was both thin and white.

Nevertheless, the Dutch adapted their techniques and were able to make a style of pottery that closely resembled the popular Chinese porcelain.

Although the Dutch pottery was still made from earthenware clay, it was often called Delft Porcelain. This was the beginning of Dutch Delftware as it is often thought of today.

The Manufacture of Delftware

To compete with the fine porcelain from China, the Dutch potters had to find new ways of making their ware. Some of the changes that took place included the following:

1) Changes to the Clay

Potters adapted the clay they used so that they could make thinner pieces that were more like porcelain. A mixture of local clay, plus clay brought in from Germany and Belgium were used.

2) Changes to the Glazing Process

Previously, the upper side of the Dutch maiolica had been glazed with the white tin glaze. The underside of the pottery was glazed with a cheaper clear lead glaze.

As a way of recreating the all-over whiteness of Chinese porcelain, the Delft potters began to tin-glaze their pieces all over.

In addition to this, like the Italian potters, they started to apply a second coat of glaze to the pottery before it was fired.

So, the first layer of glaze was the tin glaze. This was then decorated with cobalt oxide. And a final clear layer of glaze was applied over the decoration before it was fired.

During the firing process, the cobalt oxide would turn blue, recreating the sought-after Chinese style of decoration. And the top coat of clear lead glaze would give a brilliant glossy finish.

The Dutch potters managed to create an all over white finish to the Delftware through tin glazing.

However, because earthenware is relatively soft compared to porcelain, it’s not uncommon for antique Delftware to have chips and cracks in the glaze surface. You can see this typical wear and tear in the image above.

3) Changes to the Firing Process

There was also a change to the way that the pottery was fired. To protect the pots from the ash and smoke of the wood-fired kiln the Delft potters, like the Italian potters, fired their ware in saggars.

However, the Chinese porcelain didn’t have any scars on the glaze from being stacked in a kiln using spurs as described earlier. So, an alternative way of stacking the pottery was found.

Instead of using spurs, regularly spaced holes were made along the side of the saggar. Pegs were inserted into the holes and poked out on the inside of the saggar a little way. The underside of the pottery would rest on the pegs.

This was a way of separating the pots so that they didn’t weld together in the saggar. However, it also meant that any small marks from the pegs were on the underside of the pottery, rather than on the decorated topside.

You can see the peg marks on the back of this piece of delftware. Although it is not a signed piece, it is thought to have been made around 1700.

Image by Carl Guderian. (CC BY-NC-SA 2.0)

If you’d like to know more about how Delft pottery is made, you can check out my article on the processes involved here.

An Evolving Style

Over the 17th century, the history of Delft pottery changed under the influence of different imported styles of ware. They also integrated their own Dutch style into the design and decoration of pieces too. If you’d like to know more about how to identify Delft pottery, you can check out my article on that subject here.

Here are some of the influences that came from imported wares:

Kraak Porcelain

The style of Delft pottery changed over time. In the early part of the 17th century, Dutch potters focused on a particular type of Chinese pottery that is referred to as Kraak Ware or Kraak porcelain (Dutch Kraakporselein).

Kraak porcelain is thought to have been named as such because the Portuguese trading ships that brought it to the Netherlands were called ‘Kraak’ or ‘caracca’.

Kraak porcelain wares included bowls, dishes, and vases. One particular style of dish called ‘klapmuts’ was very popular in the Netherlands and copies were made by dutch potters. These dishes had a wide base and a wide rim.

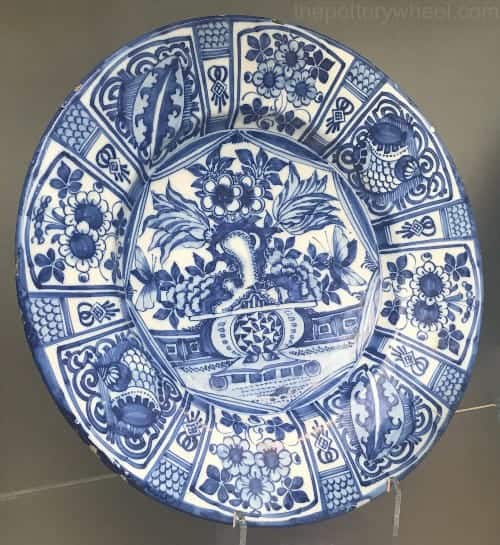

(Public Domain)

The sides of the dish were divided into panels and each panel contained its own decorative design in cobalt blue. The center of the dish was also painted with a design in blue underglaze.

Dutch potters were able to reproduce Kraak porcelain successfully using earthenware clay and tin glazing. Here is an example of a Dutch-made Kraak dish.

Artist unknown. c. 1660-80. Located at the V&A.

Transitional Ware

The Transitional Period in China stretched from 1618-1683 and was a period of stormy political change from the Ming to the Qing dynasties. Leadership changes at the top were reflected in changes in the style of ceramics being made.

But another interesting thing was happening. Chinese porcelain was influencing the pottery being made in the Netherlands. However, at the same time, Chinese potters were changing the style of their porcelain ware to suit the tastes of the countries they exported to.

So, not only was China influencing the production of pottery in the Netherlands, the Chinese potters were making pottery to appeal to the Dutch.

There were many different styles of Chinese pottery during the Transitional period. However, there was a particular type of porcelain made during this time called ‘Transitional Ware’.

Whilst some Transitional Ware was made for the Chinese domestic market, a lot of it was made to be exported to Europe and in particular the Netherlands.

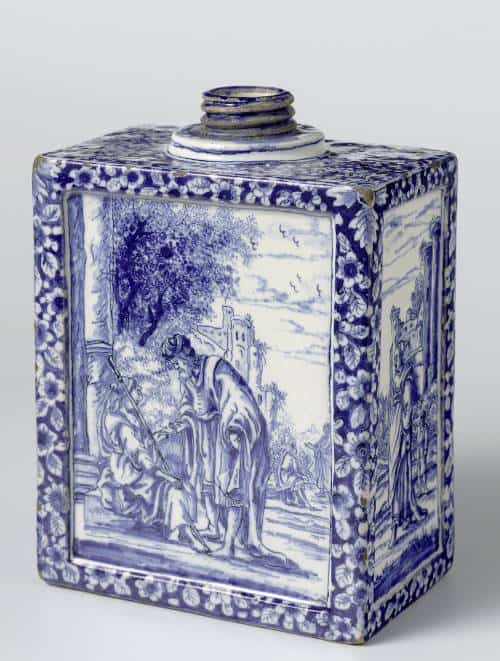

Transitional ware wasn’t divided into panels like Kraak porcelain. Instead, it was painted with blue landscapes, figures, and animals.

The decorations on Transitional ware were Chinese in style. However, the shapes of these pieces were influenced by the foreign market. In fact, the Dutch gave wooden models to the Chinese merchants indicating the shapes that they would like the Transitional ware to be made into (source).

The Japanese Influence on Delft Pottery

Around 1645, the supply of exported Chinese porcelain to the Netherlands was interrupted by political turmoil and civil unrest in China (source).

As a result, the Dutch turned elsewhere for alternative sources of porcelain. One such source was Japan.

Japanese porcelain was made in the city of Arita. For a long time, the Japanese had also been importing Chinese porcelain for domestic use. However, as the supply of Chinese porcelain declined, the production of pottery in Arita increased. Japanese porcelain of that time is called Imari porcelain, after a port from which the porcelain was exported from Japan (source).

Imari porcelain was decorated with images of people, flowers, and foliage. And it was painted in a range of colors including red, blue, and gold overglazes.

The Dutch traders started to import Imari porcelain around 1655. As a result, in the latter half of the 17th century, Delft pottery began to include colorful, red, green, and gold decorative designs. Here is an example of a Japanese Imari plate.

Painted in underglaze blue, enamels, and gilded.

Located at the V&A.

Delftware that has a range of colors is called polychrome Delft. Whereas the original blue and white Delft is referred to as being monochrome. Here is an example of polychrome Delft pottery, which draws on the Japanese Imari colors.

Courtesy of The Met (Public Domain)

The Dutch Style

The history of Delft pottery is influenced by Italy, China, and Japan. However, over the 17th Century, Delftware itself became highly sought after and valuable throughout Europe and also in China. If you’d like to know more about the value of Delft pottery please check out my article on that subject here.

As Dutch pottery itself became a market leader, the need to imitate other styles declined. And with time Delft pottery become increasingly dutch-influenced. Painted decorations on Delft pottery included Dutch styles and landscapes.

(Public Domain)

And the Delft potteries created ware that had a distinctive Dutch Delft style. They made plates, bowls, jugs, vases, tea sets, tableware, and tankards.

One of the most distinctive forms in the history of Delft pottery is the tulip vase. This is a vase, that has spouts positioned around the vase wall. The idea is that flowers, particularly tulips could be inserted into the spouts around the vase.

Courtesy of The Met (Public Domain)

Smaller tulip vases were made in one piece. But very large vases, called tulip towers were made of separate sections that contained their own water for flowers. The sections were stacked on each other to make a pyramid shape.

Delft Pottery Factories

By the end of the 17th century, there were more than 30 factories in Delft producing Delftware.

These factories were often set up in old disused breweries in Delft. The factories had their own names, such as the ‘Greek A’, the ‘White Star’, and the ‘Porceleyne Fles’. Some factories kept the same names that they had when they were breweries, for example, “The Three Bells”.

At the peak of its production during the history of Delft pottery, these factories were run by master potters. The master potters had to be a member of the Guild of St Luke. The Guild was a professional trade organization that was established to protect the interests of craftspeople and artists.

Under the management of the master potter, each task within the factory was done by a highly skilled worker. The process was very organized so that each step in the production of the Delftware happened at the right time.

Each factory had its own individual signature. This was often accompanied by a reference to the date it was made and sometimes the initials of the painter who had decorated it. To read more about each factory’s trademark, you can check out my article on Delft pottery marks here.

Not all Delftware was signed. Usually, it was the more elaborate, and expensive items that were signed. Only about one-third of the pottery produced was marked. Plenty of Delftware was intended for everyday use and left the factory unsigned.

What’s more, not all Delftware was decorated. Some had a plain white tin glaze and others were glazed black. Black Dutch Delftware is rare, and only two of the original factories made black Delftware.

(CC BY-NC-SA 2.0) Image is cropped

During the 17th century, Dutch Delftware was very popular and influential. For example, Queen Mary the II of England was an avid collector of Delftware. In fact, she was a patron of the ‘Greek A’ factory in Delft (source).

The Decline of the Delft Potteries

During the 17th century, Dutch Delftware was a thriving industry. However, during the 18th century, a few things occurred which lead to its decline.

- The price of Chinese and Japanese porcelain was falling. This created more competition for Dutch potteries (source).

- The Europeans had been trying to recreate porcelain for many years, and on March the 28th 1709, a German, Johann Friedrich Böttger finally figured out how to make it (source). The next year in 1710, the Meissen factory near Dresden in Germany started to manufacture porcelain items (source).

Other porcelain factories quickly began to open up in Germany and France. This posed further competition to the Delft potteries. - Creamware was developed in England by Whieldon and Wedgewood in the early 18th Century. Creamware was cheaper and more durable than Delftware.

- In 1768, a British china manufacturer, William Cookworthy, discovered how to make hard porcelain and set up a china factory in Plymouth, England (source).

This clay was better quality than the clay used by the Delft potters. It was hard and white when it was fired, so it didn’t need a layer of white glaze.

The Delft potteries tried to square up to this competition by lowering the quality of their production techniques. Some even tried importing English ceramics and painting them in the Dutch style.

However, gradually the Delftware potteries began to close. At the end of the 18th century, only 11 factories were open. And today only one of the original factories, De Porceleyn Fles (The Porcelain Bottle) remains open. De Porceleyne Fles is still open and making pottery today. So, let’s take a look at the history of the last remaining Delft pottery factory.

De Porceleyne Fles

De Porceleyne Fles was founded in 1653 and has been owned and run by a number of businessmen and master potters since then.

Under the rule of The Guild of St Luke, the potteries could not be run by business people and investors alone. There had to be a master potter involved at the top tier to ensure the quality of the pottery being produced and to protect the interests of the skilled workers. The Guild of St Luke was dissolved in 1833.

In the second half of the 18th Century, the Porceleyne Fles was owned by Jacobus Harlees. Harlees introduced the bottle icon into the factory’s signature mark. And a drawing of a bottle is still part of the Porceleyne Fles mark today.

In 1876, Joost Thooft took over the Porceleyne Fles factory. And his initials JT became part of the factory mark too.

In addition to the bottle icon and the initials JT, the painter often adds their own initials and a date code.

In 1919, the word ‘Royal’ (in Dutch Koninklijke) was given to De Porceleyne Fles factory by order of the Dutch Royal Family. The factory has been known as Koninklijke Porceleyne Fles or Royal Delft since then.

The History of Delft Pottery Production Methods

Joost Thooft was the driving force in the history of delft pottery behind some significant changes at De Porceleyne Fles. He researched and experimented with different clays, glazes, and painting techniques.

It was whilst Thooft ran the factory, that there was a move away from tin glazing. Instead, the pottery moved towards something akin to how contemporary ceramics are often made. The pieces were bisque fired, decorated and then a clear glaze was applied over the top.

Thooft also experimented to improve the clarity and detail in the Delft designs. And after a period of experimentation, the factory managed to produce defined details with shading in their decoration using the new painting techniques.

Modern Delftware

The clay used by the Royal Delft today is made up of a number of different raw materials including kaolin, feldspar, quartz, and chalk.

These raw powdered clays are mixed together with water to create a liquid clay suspension called slip. To create a piece of pottery, the slip is poured into a plaster mold of the piece.

The slip is allowed to sit in the mold briefly and the plaster will draw out some of the water from the clay slip. This will create a skin of clay on the inside plaster mold. The excess clay slip is poured out and the clay skin is allowed to dry in the mold until it is leather-hard.

The mold is then removed, and any imperfections on the clay piece like seams from the mold are tidied up. It is at this point that other details like clay spouts can be added to the pottery.

Before it is fired in the kiln the pottery is covered with a coat of white engobe, which is a kind of colored clay slip.

After it has dried out completely, the piece is then fired for the first time. It is after this biscuit firing that the Delftware is decorated.

Muesse, (CC BY 3.0.) via Wikimedia Commons

Some pieces of pottery such as plates are made on the potter’s wheel. But a lot of the pottery made at the Royal Delft is made through the process of slip casting described above.

Decorating Delftware

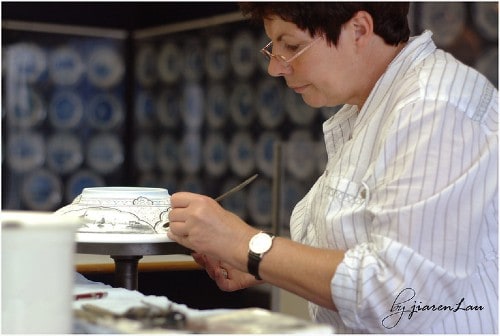

The painters at De Porceleyne Fles sketch out their designs lightly with charcoal or pencil.

They might also use a piece of paper with the design on it. Small holes are made in the outline of the design on the paper.

This is then held up against the pottery and dusted lightly with charcoal. An impression of the design is left on the pottery where the charcoal has come through the paper.

The design is then painted onto the pottery using an underglaze mixture made mainly from cobalt oxide. To create lighter shades the underglaze is watered down.

‘The Potter’s Hand‘ by Jiaren Lau (CC BY 2.0)

Glazing and Firing Delftware

Once the decoration is finished, the pottery is glazed with a clear glaze. Lead-based glazes are no longer used. The glaze is applied by dipping the piece in glaze. Alternatively, it is sprayed onto the piece using an airbrush and compressor.

The pottery is then fired a second time to melt the glaze onto the piece. Glaze firing is now done in large electric kilns, rather than the original wood firing kilns that were used at the Delft factories.

Electric kilns have several advantages. Firstly, ash and dirt don’t fill an electric kiln, so the Delftware doesn’t need to be fired in saggars anymore. Secondly, it’s much easier to control the temperature on an electric kiln. The wood-fired kilns of the old potteries were very labor intensive and had to be tended to by kiln stokers constantly to make sure the kiln was at the right temperature.

Modern Mass Production of Delft Pottery

De Porceleyne Fles is the last remaining of the original factories that span the history of Delft pottery. Another one of the older factories called De Delftse Pauw or the Delft Peacock was a smaller family-run business and sadly closed down in 2020.

However, a number of smaller potteries now exist in Delft and other parts of Holland. These smaller potteries copy the blue ‘delft style’ using the same motifs, such as windmills and flowers.

A lot of the pottery produced by the smaller factories is less expensive and doesn’t have the same level of craftsmanship found on the original Delftware.

Some of these mass-produced items are hand painted. However, some of the designs are laser printed onto the pottery, and some are manufactured in China and shipped back to the Netherlands to be sold to tourists.

Because of the large amount of tourist focussed ceramics that are in the style of Delftware, it can be tricky to spot the real thing. However, a trained eye and a knowledge of the marking system used by the Delft factories can help.

The History of Delft Pottery in Other Countries

A history of delftware is not complete without mentioning that Delftware is made in other parts of holland, not just Delft. For example, in the 16th century, there were Delft factories in other Dutch cities, including Haarlem, Amsterdam, and Middelburgh.

The oldest ceramics company in the Netherlands is the Makkum Factor of Tichellar. It was founded in 1572 and is still open today and specializes in tile manufacture.

Tin-glazed ceramics were made in a number of European countries. As mentioned earlier on, they were made in Italy and Spain and called Maiolica. However, the tin-glazed pottery in Britain was actually called Delftware.

c. 1670-85. Located at the V&A

English Delft was originally called Galleyware (Gallyware). It got this name because originally tin-glazed pottery was exported to the UK from Venice in the galley of ships.

The name Gallyware was then replaced in England with the name Delft. English Delft was produced in a number of cities, including amongst others London, Bristol, and Liverpool.

Final Thoughts

The history of Delft pottery spans centuries, between countries and continents. It’s a history in which other cultures and styles of ceramics influence the Dutch potters. But it is also a history in which the Delft potters in turn become influential trendsetters. The fact that only one of the original factories remains in operation is bittersweet. Nevertheless, we are lucky that De Porceleyne Fles continues to carry on the Delftware tradition.

References

- “Royal Delft: A Guide to De Porceleyne Fles. Erickson, E, 2003 p.9.