Your cart is currently empty!

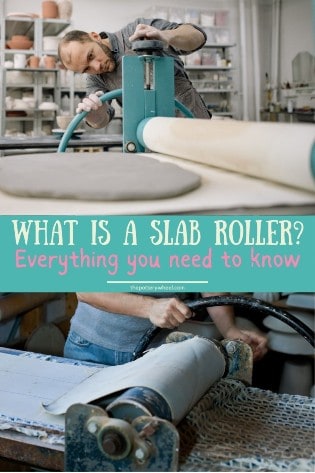

What is a Slab Roller? Everything You Need to Know

Published:

Last Updated:

Affiliate Disclaimer

As an affiliate, we may earn a commission from qualifying purchases. We get commissions for purchases made through links on this website from Amazon and other third parties.

There are lots of different ways to make nice even smooth clay slabs for slab pottery. One way to make a slab is to use a slab roller. But what is a slab roller? And how does it work?

A slab roller is a piece of equipment, that makes large slabs of clay easily. Clay is fed through a mechanism mounted on the slab roller. The mechanism is made of one or two large rollers positioned above some wooden boards. As the clay is squeezed through the rollers, it is flattened into a slab.

Slab rollers come in different sizes and sizes. They range from mini portable tabletop slab rollers that are about 24 inches long. All the way up to huge 60-inch long free-standing sturdy slab rollers that can make enormous slabs of clay.

Regardless of their size, they all work on the same principle. And that is to feed your clay through a narrow gap on the slab roller to flatten it into a slab.

So, let’s take a closer look at how they work and what some of the differences are…

Different Types of Slab Roller

Broadly speaking there are two different types of slab roller. Some slab rollers have one roller to compress the clay, others have two rollers. Here are some of the differences between these two models:

Type 1

The first type of slab roller consists of a table, over which a heavy single roller is mounted. The roller is moved across the table using a lever, wheel, or handle, depending on the model.

A mound of clay is placed on the table. The roller travels across the table, compressing the clay into a flattened slab.

In order to prevent the clay from sticking to the table and the roller, the clay is sandwiched between a folded piece of canvas.

Using canvas to sandwich the clay is important because if the clay gets stuck to the roller mechanism it’s very time-consuming to clean it off.

(CC BY-NC-ND 2.0)

How Does the Slab Roller Work?

Often with this type of single roller design, there is actually a second roller positioned beneath the table. You can see the second roller clearly on this Brent Mini Slab Roller below.

Both of the rollers are attached to a wire pulley system. The rollers are bound together by strong wire that is wrapped around them in a figure of eight. Both rollers move together as the handle is turned.

Brent Mini SRC Slab Roller – View on Blick

To operate it, the handle is turned to move the roller back to the top end of the table. Prior to turning the handle, the potter folds the clay in the canvas and presses it up against the roller. This ensures that when the roller starts to move, it ‘bites into’ the clay and starts to travel over it.

Adjusting The Thickness of the Slab

With this design, the gap between the roller and the worktop is fixed. This is because the rollers are bound together and are moved with a taut cable drive system. As such the roller can’t be moved up and down because doing this would affect the tension of the wire.

As a result, the gap through which the clay passes can’t be adjusted on the roller. In theory, this means that the slab roller can only produce slabs of a single thickness.

However, the size of the gap between the roller and the work surface can be altered in a different way. Sheets of board (or shims) can be placed on the tabletop beneath the roller.

The sheets of board reduce the size of the gap between the work surface and the roller. This enables you to make slabs of different thicknesses. The width of the gap is determined by the thickness or the number of boards used.

One limitation that is sometimes leveled at this type of slab roller is that it’s harder to fine-tune the thickness of your clay slab.

Whilst you can use boards, or shims to adjust your slab, it’s not the easiest method. And you are limited by the thickness of the boards that you have.

The second type of slab roller uses a different mechanism that allows for easy fine-tuning. So, let’s take a look at that design now.

Type 2

There are two main differences with this second style of slab roller. The first difference is that the rollers don’t move up and down the table. They are mounted in a static position on the worktop. Instead, the clay moves with the canvas through the rollers.

The second difference is that the clay is compressed between two rollers rather than one roller and the worktop.

This design works a lot like an old-fashioned clothes mangle. The handle turns the rollers using a gear system. As the rollers turn they grip onto the canvas and clay and drag it through a gap between them. When the clay passes between the two rollers it is compressed into a slab.

Adjusting the Thickness of the Slab

The top roller can be moved up and down to adjust the gap between the two rollers. This adjustment is made by turning a knob or lever on the top of the slab roller.

Exactly how to make the adjustment depends on the make or model. But most designs have a knob, lever, or handle that rotates to allow you to adjust the gap.

There is also normally a gauge on the side that indicates how big the gap is and how thick your slab will be.

The advantage of this type of slab roller is that usually, you can fine-tune the gap to be exactly the size that you want it to be.

Tips for Using a Slab Roller

Here are a few tips to bear in mind when using a slab roller:

- Slab rollers are strong. Nevertheless, it’s best to flatten out your clay a bit before you try to put it through the roller. If you try to pass a very large lumpy bit of clay through the slab roller it will be hard work to turn the handle.

But more importantly, it can put a strain on the gears or wires that activate the rollers. This can damage your equipment.

You can flatten the clay out a bit with the heel of your hand or your fist. Or if you are working with a very large piece of clay, you can pound it into a flattened shape with a rolling pin. - It can help the rolling process to flatten the leading edge of your clay into a tapered shape, a bit like an axe head. This will help the clay engage with the rollers so that the rollers grip the clay and begin the process of compressing it into a slab.

- The clay will be stretched in the direction that the roller or the canvas is traveling. So, as you roll the clay will be elongated. Using the slab roller won’t add width to a slab of clay. If you want your clay to be a particular width, you need to shape the clay you start off with so that it’s the right width for you.

Using a Slab Roller in Your Creative Design

It’s easy to think that making slabs is a bit like making building blocks. And that the creative bit starts once you have made your slabs. However, slab rollers can also be used during the making process.

Some potters will cut out pieces of their slabs. Then once they have decorated them with texture, slip, or underglaze, they layer the pieces together.

If these pieces are positioned thoughtfully, they can be passed through the slab roller again. This will compress the decorated slabs together to create a new integrated slab decorated with exciting shapes and designs.

The Benefits of Using a Slab Roller

Here are some of the benefits that come with using a slab roller…

- It’s very easy to make a large slab. Even with a long rolling pin, you would struggle to make a slab as large and as even as a slab made on a large slab roller.

- Slab rollers are practical if you need to produce a high volume of slab pottery each day.

- You can create a batch of slabs with exactly the same width.

- When you turn the handle on the slab roller in a smooth consistent motion, you create very even smooth slabs

- Larger slab rollers are mounted on large heavy tables. These can double up in your studio as a workbench. Also, because they are so solid, they make good wedging tables, as they don’t move about as you are wedging.

Do You Really Need a Slab Roller?

That being said, a slab roller is a significant investment. Can you survive without one?

Absolutely. There are lots of different ways to make a slab of clay. Here are some alternatives:

- Rolling your clay with a rolling pin

- Slicing it with a bow harp clay slicer

- Slamming the clay at an angle on your worktop

- Dropping the clay on your floor

- Pound the clay flat with your hands or a rolling pin

- Using a paddle

If you’d like to know more about some alternative ways to make great slabs, check out my guide on making slabs here.

Final Thoughts

That being said, if you have the space and the resources for a slab roller, they do make a great addition to your studio.

Personally, my own home pottery studio is a micro-studio. I think a real estate agent would call it bijou! Having a slab roller in there isn’t practical. However, I do use the slab roller at my local ceramics studio and it does make life a lot easier.