Your cart is currently empty!

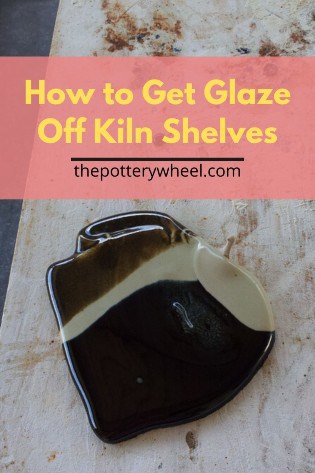

How to Get Glaze Off Kiln Shelves? – Easy Glaze Removal

Published:

Last Updated:

Affiliate Disclaimer

As an affiliate, we may earn a commission from qualifying purchases. We get commissions for purchases made through links on this website from Amazon and other third parties.

Finding that your glaze has run off your pottery and onto the kiln shelf is not unusual. Especially if you are learning about glazing, or using an unfamiliar glaze. Most potters have a kiln shelf or two that have been damaged by running glaze. In practice, it is not ideal for your pottery or your shelf if the glaze is left on. So, how do you get glaze off kiln shelves?

There are two main ways to get glaze of kiln shelves. The first is to use a hammer and chisel and the second is to use an angle grinder. The chisel method requires caution to avoid breaking the shelf. With an angle grinder, you need to avoid making gouges on the shelf.

You can combine both methods or stick to the one that works best for you. But, what is best avoided is leaving the glaze stuck onto the kiln shelf. If you do, with time, the glaze will melt deeper into the shelf, becoming more embedded. Even if you used kiln wash, the glaze can soak through it and stick to or discolor your pots.

Why You Need to Get the Glaze Off Kiln Shelves

Firing and glazing can be unpredictable processes. And when using a new glaze or glaze combinations accidents can occur.

Therefore, it is important to equip yourself with simple tactics to get the glaze off the kiln shelves.

It’s a good idea to remove any drips of melted glaze before subsequent firings. Otherwise, the glaze can work its way further into the shelf. This will compromise the integrity of the kiln shelf.

And, in the long run, it’ll become more difficult to scrape the glaze off because it has become more embedded. As a result, you will have to cut deeper into the shelf to get rid of it completely.

Before long, the shelves will need to be replaced, so you probably want to avoid that. Removing stubborn glaze from kiln shelves might prove hard at first, but with time, you’ll master it.

Best Ways to Get Glaze Off Kiln Shelves

Here are some of the best ways to get glaze of kiln selves without damaging the shelf.

Method 1: Using Hammer and Chisel

This is more like a brutal method for getting the job done. Using a hammer and sharp chisel allows you to target the specific areas where the glaze is melted on.

However, before chiseling it is recommended that you place the shelves on a soft surface like an old cushion. An alternative is a bed of sand or foam rubber.

Hold the shelf against your legs in a near-vertical fashion, and then slowly hammer the chisel into the glaze drip. A good rule of thumb when doing this is never to hold the chisel vertically against the shelf.

When chiseling off built-up glaze from kiln shelves, it is best to use a sharpened chisel to get the best result. In addition, you want to be careful while applying pressure so as not to chisel into the shelves.

If the build-up is not serious, you can use a putty knife to get the glaze off kiln shelves. It’s easy when chiseling off glaze to gouge into the kiln itself. Using a chisel well is an art in itself. If you do gouge a bit into the shelf, you can try smoothing this out with some kiln wash.

However, it’s not a good idea to apply kiln wash over the melted glaze. The glaze will still melt when the kiln is re-fired and can transfer onto your pottery.

Further Precautions

Always wear a protective covering while chipping off the melted glaze. You want to avoid shards of glaze flying into your face. To avoid this, wear safety goggles or a face shield. Also, use a good dust mask when chiseling.

Method 2: Using Angle Grinders

Another smart and efficient method to get glaze off your kiln shelves is using an angle grinder. There is a variety of these, depending on the nature or thickness of the glaze to be scrapped off.

You can get a standard angle grinder from online stores for a few dollars. Typically, a 4½ or 5-inch angle grinder is ideal for most studio tasks.

For industrial uses, a 7-inch angle grinder can be used. For light grinding, fiberglass reinforced grinding disks work fine. More serious grinding or for leveling out irregular shelves requires a heavy-duty diamond cup wheel. In fact, there are two different types of discs that are suitable for grinding off melted glazes. These are…

A Masonry-Duty Silicon Carbide Disc

The first option is a masonry-duty Silicon Carbide disc or wheel and the second is a flap disc. The Silicon Carbide disc will make light work of removing the glaze. However, it may also gouge the shelf, so you want to be careful with it. You can use it with a hand-held grinder.

Before you begin, place the shelf on a flat surface that is free of debris. It is usually best to hold the grinder at an angle that is close to horizontal. It is also advisable to start slowly and gently, especially if you are not experienced with this kind of tool. The grinder will do the work but it must be positioned correctly.

Therefore, you need to be very careful with it, because it can cut right through the glaze and the shelf. This happens if you apply too much pressure or hold the grinder at the wrong angle. It’s best to keep the angle of the disc low. Also, don’t stroke too far forward with the edge of the disc.

The Flap Disc

The flap disc, on the other hand, is best for removing kiln wash from the shelves. In addition to leaving a perfectly smooth surface, it will not gouge the surface of the shelf.

The flap disc is often easier to handle than the Silicon Carbide disc. If you have difficulties using the Silicon Carbide disc, you can opt for the flap disk until you get the hang of it.

Further Precautions

You may notice that fired glaze is harder than the kiln shelves. Kiln shelves are made out of soft brick. So, if you are too aggressive when handling a grinder, you can easily cut deep gouges in the shelves. It’s important to avoid this, gouging out chunks of the shelf will weaken the shelf.

Secondly, you will need to wear a good protective covering for your face. In particular, it’s a good idea to wear a dust mask and a pair of goggles during the operation.

You may also need to wet the area with the glaze before grinding. This makes the process a bit easier. However, you`ll have to dry the shelf properly before sending it back into the kiln.

Method 3: Use Sufficient Kiln Wash

Applying kiln wash is a preventive measure to avoid the build-up of glaze on the shelves. Aside from that, it makes it easier to get the glaze off kiln shelves if it does happen to drip.

After thoroughly cleaning your shelf, be sure to apply kiln wash on the shelf before reusing it. Although melted glaze could still work its way through the kiln wash, it’s a great way to protect the shelves.

Be sure to make the coating of the kiln wash thick enough as glaze can penetrate a thin coating. A good kiln wash can also prevent glazed pots from cracking when removing them from the shelf.

Prevention is Better Than Cure

There are two main reasons that kilns can run off your pottery onto the shelf. They are:

- The glaze has been applied too thickly

- Your pottery has been fired too hot for that particular glaze

To avoid running glaze, you can address these two issues.

- Firstly, avoid putting too many layers of glaze on your pieces.

If you are dipping your pottery you may get good glaze coverage after one decent dip. There may be no need to dip a second time.

If you are brushing your glaze, often 2 coats are sufficient. 3 coats of brushed glaze really should be the maximum. - Secondly, make sure you check what temperature the glaze is designed to be fired to. Avoid putting a low fire glaze in a mid-range or high-temperature firing.

A related point is to monitor the kiln to avoid overfiring(1). If an unattended kiln over-fires, you can end up with puddles of melted glaze and clay on the kiln shelf. - Thirdly, consider using kiln cookies. These are thin biscuit or cookie-shaped patties of clay that your pottery sits on when being glazed.

They act a little like a coaster under a mug on a table. Any drips of glaze stick to the cookie. The cookie will then need to be separated from the glaze that has dripped down the side. But at least your kiln shelves have been spared.

Final Thoughts

Getting glaze off kiln shelves may seem like an impossible task, especially if you are still new to firing pottery. The two methods highlighted in this article are quite easy to learn and use. Before long, you`ll become adept with the process.