Making pottery pre-dates the invention of the pottery wheel by many thousands of years. One of the most extensively used methods for making early pottery was the coiling technique. Early historical coil pots have been found across the globe. Many of the techniques currently used to make coil pots date back to pre-historical times. This article looks at the history of coil pots between different continents over the millennia.

Use these links below to jump to information about historical coil pots from a particular region.

Historical Coil Pots from Africa

It’s thought that pottery in Africa first started around 7000 or 6000 BC. It began in East Africa and slowly spread to West and then North Africa.

In spite of its long history, knowledge about traditional African ceramics is a little limited. The lack of information about African ceramics is noted by Texan art historian Diana Lyn Roberts. She points out that until recently, African ceramics has had a “somewhat peripheral position in Western artistic consciousness” (source).

Similarly, Bickford Berzock points out that there are “gaps in literature” on African ceramics (source).

What we know about how pottery was made in Africa in the past is based on how it’s currently made. Many of the traditional ways of hand-building pottery, including coil pottery have remained the same over the years.

This is true not just of Africa, but worldwide. For example, a tribe in Yunnan in China still makes pottery in the way it was made in prehistoric times. (Blandino, B. 1984).

So, much of our understanding of historical coil pots from Africa is based on current ceramic techniques.

African Ceramic Techniques

What we do know about early African pottery is that it was mostly made by women. It was fashioned by hand often using the coiling technique.

First, the clay was mined and prepared. Water was added to make the clay more workable. Then gritty material was added to reduce the amount that the pottery shrunk as it dried. The material used as grit, or ‘grog’ was sand, broken pebbles, old pottery, dry grass, or dung.

(CC BY-SA 3.0) via Wikimedia Commons

The pottery was most often constructed using coils of clay. When the pot had been built, it was allowed to dry in the sun. The coil pots were fired in a wood fire, either in an open bonfire or a pit.

The pit might be dug into the ground. Or a simple kiln is made by building a low brick wall in the shape of a circle. Wood and/or dung was then put into the brick kiln and the pottery was placed on top. Air holes in the base of the wall would allow oxygen to feed the fire in the kiln.

Traditions that Have Survived

Many of these traditional methods of making pottery are still current in Africa today.

Clay is dug up from the ground. Because of the dry climate, it needs to be mixed with water to make it workable. The dried clay is ground down to a powder using a wooden pole like a mortar and pestle.

Old fired ceramics are broken up into a gritty powder to make grog. The grog is mixed with the clay powder and water is added to mix up the clay body.

Sometimes coils are to make an entire pot. Other times, coils are added to the pot that has been initially formed using a mold.

Africa is of course a vast continent and it’s impossible to give an overview of all the coiling techniques used. However, in spite of regional differences, there are some shared techniques.

The following description of a coiling technique used for centuries in Western Africa is a good general example.

African Coil Pottery

One of the traditional approaches to coil pottery in Africa is evidenced in Burkina Faso in West Africa. When making very large pots, the potter walks around the vessel adding coils.

To build up the walls of the pot the upper lip of the clay is scraped. This scraping creates a level rim and gives the rim a rough surface.

The rough clay surface helps the new coil of clay to stick to the existing pot. This is the same principle behind slip and score used by many contemporary potters.

A piece of clay is then shaped into a thick coil of clay. The coil is pressed using both hands against the rim of the pot. If the pot is very large the coil may be broken into sections and added in segments.

The clay is smoothed using a combination of solid tools, wet hands, and wet fabric.

(CC BY-SA 3.0), via Wikimedia Commons

An alternative approach is used by the Igbo potters in southern Nigeria. This method is used to make smaller pots. A disc of clay is shaped by hand to form the base of a pot. The disc is then placed in a mold which provides support as the potter works on the piece.

Once supported, the disc is scraped and the edges curled up to form the start of the pot walls. Coils of clay are added to build the walls of the pot upward.

Once enough clay has been added with coils the walls are shaped and thinned and smoothed using a wooden tool.

(CC BY-SA 3.0), via Wikimedia Commons

Historical Coil Pots from Asia

Asia is of course a huge continent. So, it wouldn’t be possible to talk about all the historical coil pots from Asia in one article. Nevertheless, here are some important developments in the history of coil pottery in that region of the globe.

Coil Pottery in the Middle East

The Middle East is often quoted as being the birthplace of pottery production on a wider scale. Ancient Mesopotamia, or as it is now known southern Iraq, is thought of as being where large urban civilizations developed.

By 3000 BC, the cities of Mesopotamia were busy with craft and commercial trade. The production of pottery was a skill that was part of the trading culture. Prior to the introduction of the pottery wheel, almost all pottery was made in Mesopotamia using the coiling technique.

During this period, it was mainly women who made pottery. Because they were often child-rearing, they worked close to home and the work was part-time.

The technique of making coil pots involved pressing clay coils against the rim of a pot then smoothing out the surface. Clay coils were smoothed either with fingers, a piece of wood, or an old bone.

To speed up the process the potters would position the base of the pot on a plate or another pot. This would allow them to turn the pot being worked on more easily. The supporting pot would be held on the ground, their lap, or on a table.

Coiling and The Pottery Wheel

The production of pottery was speeded up a lot by the development of the pottery wheel. The pottery wheel was a crucial invention because it enabled the production of pottery to be scaled up.

Making enough pottery to store and contain produce, and feed the population enabled an expansion in many areas of life.

Around 4000 BC the wheel, in general, started to be used in Mesopotamia. Wheels were used to help move heavy items about and the first early carts were developed. As the principle of the wheel began to revolutionize ways of working, it also began to impact pottery making.

In approximately 3000 BC, potters would use a simple turntable, or tournette, to rotate their pottery as they added coils.

Eventually, faster pottery wheels that used the principle of the flywheel were invented. This enabled pottery to be made using the wheel throwing techniques that we recognize today.

The invention of the wheel enabled pottery production to expand. Nevertheless, throwing pottery on the wheel did not completely replace making coil pots in the Middle East.

Having faster wheels has enabled potters to make coil pots faster. The pottery wheel was used to turn the pottery and add bigger coils of clay to the piece more quickly.

Potters add large, soft coils of clay quickly to the pot and smooth it as it rotates on the wheel. This method is still popular today in the Middle East, Asia, and the Mediterranean.

Coil Pottery in Japan

The Jomon Period is the earliest era in Japanese history. It began around 14500 BC and ended around 300 BC. The start of the Jomon Period coincided with the Neolithic Period in Asia and Europe (source).

This period was actually named after the corded pottery that was made in that era. Jomon means ‘rope patterned’ and refers to the use of rope to add texture to the surface of the pot.

It was also a long episode in Japanese history, and historians divide the era into six phases (source). Each phase has an associated style of Jomon pottery. These different styles have their own individual characteristics.

Examples of Jomon Pottery

Jomon pottery from the early period of 4,000 to 3,000 BC typically had incised decoration. Here is an example of this style of Jomon pottery.

By contrast, Jomon pottery from the period of 3,000 to 1,000 BC often had elaborate decorative designs. These would often have a flame-like design. Archeologists call these pots ‘fire-flame’ pots.

In spite of the various differences in style of pottery over the era, all Jomon pottery was made by coiling. The clay used to make these historical coil pots was sometimes tempered using grog like substances.

These additions to the clay would include crushed shells, lead, and fibers. Another ingredient sometimes added to the clay was phlogopite (source). This heat resistant mineral was found in the mountains of Tokyo and also in the streams of the Kanto region.

Because it is refractory, or heat resistant, the phlogopite, reduced the amount the pottery shrunk as it was fired. Jomon pottery was low fired at temperatures below 1650F (900C). Because the phlogopite remains stable at higher temperatures, it kept its size and shape at lower firing temperatures.

Coil Pottery in China

The Yangshao period in China was part of the later Neolithic era and dated from 5,000 to 3,000 BC. The Yangshao culture was made up of hundreds of settlements. These were positioned along the Yellow River and Wei River regions of China. The Yangshao settlements stretched across northern China to the Gansu province.

This Chinese culture was known for its historical coil pots. They were made by stacking and joining coils of clay, then smoothing the clay with paddles and scrapers (source). Yangshao pottery was often storage jars, with full, curved bodies. However, they also made rounded bowls with flat bases.

This pottery is famously known for its painted decorations. The designs were often geometrical but also include flowers, faces, fish, and animals. Generally, the designs were painted in red and black. Typically, though not always, the painted designs were applied to the upper half of the pottery.

Coil Pottery in India

Pottery in India has traditionally been made using a variety of methods. These include beating the clay into shape and using molds to make pots. Potter’s wheels have also been used for many years.

In India, a traditional potter’s wheel is either a large wooden wheel that has spokes like a cart wheel. Or it is made of heavy stone. The potter squats on the ground next to the wheel. The wheel starts spinning by using a stick that is poked into the wheel head and used as a lever.

In some areas of India, for example, Kutch, coil pottery is only used to make pots for storage or toys. (source). The methods used today are the same methods used to make historical coil pots.

For large storage pots, a slab of clay is positioned on a fired bat. The walls of the pot were then built up using thick coils. These storage pots are large, sometimes reaching 1 meter in height.

These pots are fired and sometimes decorated with slip or more coils. In some parts of India, more coils are added as the amount of grain stored in the pot goes up.

In other parts of India coiling is used to make pots for food, toys, and artifacts like figurines and goddesses. For these smaller items coils are placed upon a stone disc. The disc, which acts like a banding wheel, is easily rotated by hand as the coil walls are built up.

Charai Taba Pottery

There is a small group of potters in the town of Andro in Manipur a state in North-Eastern India. This group of potters, who are part of the Sanamahi culture, has maintained a long historical tradition of making Charai Taba pottery.

Charai Taba pottery is made using the coiling technique. These historical coil pots are made by married women. And the technique involved is passed from mother-in-law to younger women.

Charai Taba pottery has been made since before the 1700s. It is used for storing seeds, cooking, and drinking vessels. It is also used to ferment an alcoholic rice brew that has a ritual significance.

Image courtesy of Sanjiv Valsan @Sanjiv Valsan & Facebook

The Charai Taba pottery is made by women adding loops of clay on top of one another. The pieces typically have curved sides that are made by adding smaller or larger coils as required.

Historical Coil Pots from Europe

From the Neolithic era to the bronze age, most ceramics in Europe was made through coil construction.

Neolithic means the new Stone Age. This era lasted until around 3,300 B.C. and it ended when the Bronze Age began.

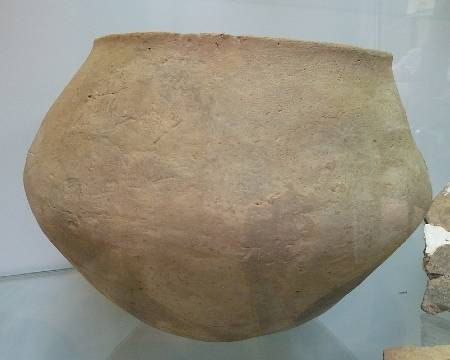

Early Neolithic pots were round-bottomed pots, that were used for cooking and storing food. They were made to sit in the ashes of a fire to cook food. They usually had an undecorated burnished surface.

During the Neolithic pots would be made from naturally sourced local clay that was dug up from the ground. Stones and roots would be removed from the clay to make it workable. Prehistoric pots would be made either by beating the clay into shape over a mold. Or they would be built using clay coils or rings.

In the middle part of the Neolithic era, the decoration of pottery began. This would be done using cord. The cord would sometimes be twisted around a stick and pressed into the wet clay. Other primitive ways of incising the pottery involved using fingernails, fingers, reeds, quills from feathers, or small bones. Pottery decorated with cord was known as Corded Ware.

(CC BY-SA 3.0), via Wikimedia Commons

In Britain, a particular type of coil pot developed during the Neolithic era. This was known as Grooved Ware. It typically had a flat bottom, with straight sides that graduated outwards. It also had decorative grooves carved into the top edge of the pot.

Beaker Ware

Towards the end of the Neolithic era and the start of the Bronze age, a new type of pottery emerged in Iberia. It was a beaker with the shape of an inverted bell. Hence it has been known as Bell Beaker Ware, or Beaker Ware for short.

Beaker Ware became prevalent across Europe. It was coil-built and had a round-shaped bottom. Generally, they had a very decorated surface and had a curvey S-shaped profile (source)

Early pots from the Neolithic era and early Bronze age were grog tempered. This means that various gritty substances, either sand, shells, bones, or broken pottery were added to the clay.

The purpose of this was to make the sticky naturally sourced clay more workable. It also prevented the pottery from cracking when it was fired either in a bonfire or a pit fire.

Iron Age Pottery

Until wheel throwing was invented most pottery was made through coiling or slab construction, or a mixture of the two.

Prior to the invention of the wheel, pottery would be placed on mats or leaves. This would enable the potter to turn the pot as they coiled, rather than having to walk around the pot. Large coil pots would sometimes be made by adding the coil whilst moving around the pot.

Early wheels are thought to be a development of the practice of putting pots on mats and turning the mat. The earliest forms of pottery wheel were plinths that could be turned by foot. These are known as tournettes. As the tournette was turned the potter would add the coil to the pot.

Later wheels utilized the flywheel principle, which enabled the wheel to turn much faster. This was the beginning of what is known today as wheel throwing.

In some regions of the world, pottery wheels that used the flywheel principle developed as early as the Iron age. However, in other countries, such as Britain, wheel throwing wasn’t introduced until the end of the Iron Age. Until that point coiling was the predominant way of making pottery.

Romaine, CC0, via Wikimedia Commons

Historical Coil Pots from North America

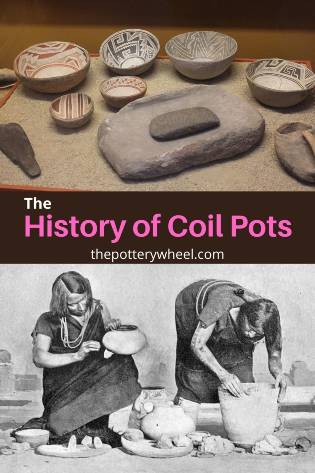

Much of the oldest Native American pottery documented was produced by three pre-Colombian Indian cultures. These cultures were the Mogollon, the Hohokam, and the Ancestral Pueblo people, also known as the Anasazi.

There is very little evidence of pottery having been produced on the potter’s wheel during this period. All early Native American pottery seems to have been hand-built. Coiling was in particular the preferred method of making vessels. This was partly because it is easier to make larger pots suitable for storage using the coiling method.

The production of coil pottery is said to have begun in Central Mexico around 2,000 BC. Over the next two thousand years, the production and use of coil pottery spread northwards. Eventually, it reached the regions of Mogollon, Hohokam, and Anasazi.

In the early part of the first millennium, the Ancestral Pueblo, the Mogollon, and the Hohokam people all produced pottery. Initially, their handmade coil pottery was very utilitarian.

These historical coil pots lacked decoration and often the original coiled and pinched texture was left visible. The pots were a bit rough and ready, often somewhat asymmetrical and lacking in artistry.

How Native American Coiled Pottery Was Made

The Hohokam used the ‘paddle and anvil’ approach to making their coil pots. Whereas the Anasazi and Mogollon potters used the ‘coil and scrape’ method (source).

The paddle and anvil approach involves using a paddle as a beating tool. This might be a wooden bat or a stone. The anvil is held on the inside of the pot and supports the clay. The anvil might be a curved piece of fired clay or stone. Then the vessel is beaten from the outside to build and shape the pot.

The coil and scrape method of coil pottery involves building the sides of the pot up using coils of clay. These coils are then pressed and pinched together to attach the clay.

The surface of the pot is then smoothed by scraping the ridged coil surface away. Often a piece of shaped wood, gourd (a hard-shelled plant), or broken pottery was used as a scraper (source).

How Native American Coiled Pottery Was Made

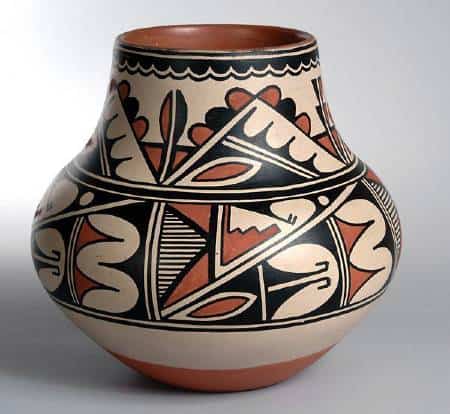

Over time, each of these cultures refined their techniques and developed their own distinctive designs.

Daderot, Public domain, via Wikimedia Commons

Hohokam pottery was generally made from light brown clay and decorated with geometric designs. These were often red-colored and used repeating patterns.

By contrast, earlier ancestral Puebloan and Mogollon pottery was often ‘black on white’. This design style is so-called because the clay used was white-colored. And the painted designs were black.

The Anasazi tended to use black paint made from boiled plants. Whereas, the Hohokam often used paint made from crushed rock that contained iron.

Contemporary Indian Tribes

For a number of reasons, all three of these early Native American cultures gradually declined. And eventually, by the end of the 15th Century, each of them had disappeared.

Some modern tribes trace their origins back to the ancestral Puebloans. These tribes include the Acoma, Hopi, Laguna, and Zuni. Other modern tribes attribute their descent to the Hohokam culture.

A rich tradition of coil pottery continues to flourish amongst Native American tribes to date. A lot of the pottery made is produced to meet demand in America. This is because Native American coil pottery has become highly collectible worldwide.

Some Native American coil pottery artists such as the Navajo potter Louise Goodman have achieved international recognition. Another well-known native American potter is Maria Martinez (1884-1980), who also made coil pottery.

Public domain, via Wikimedia Commons

Final Thoughts on Historical Coil Pots

Coil pottery has had an enduring influence over ceramics worldwide. This has been a brief whistle-stop tour of only some historical coil pots. There is a lot more about the history of coil pots that has not even been touched upon. However, hopefully, it has been a useful starting point for anyone wanting to know more.